Haufinyane tjena, TENSE e phethile ka katleho ho fana ka mokhoa o hlophisitsoengmochini o moholo oa tanka e le 'ngoe o hloekisang oa ultrasonicbakeng sa moreki indastering ea likarolo tsa likoloi. Mochine o ne o entsoe ka ho khetheha ho sebetsana le likarolo tse kholo le tse boima tse nang le litlhoko tse phahameng tsa ho hloekisa. Ka mor'a ho feta tlhahlobo e feletseng ea ka hare, thepa e se e rometsoe sebakeng sa bareki.

Ho fapana le mekhoa e tloaelehileng ea ho hloekisa, morero ona o ne o hloka atharollo e seng ea maemoe etselitsoeng tšebetso ea moreki. Sistimi e fanoeng e kopanya ho hloekisa ka matla a matla a ultrasonic ka boits'oaro bo bohlale, e ikemiselitseng ho fokotsa haholo tlhahiso ea basebetsi ha e ntse e ntlafatsa ho hloekisoa ho nepahetseng le ho tsitsa.

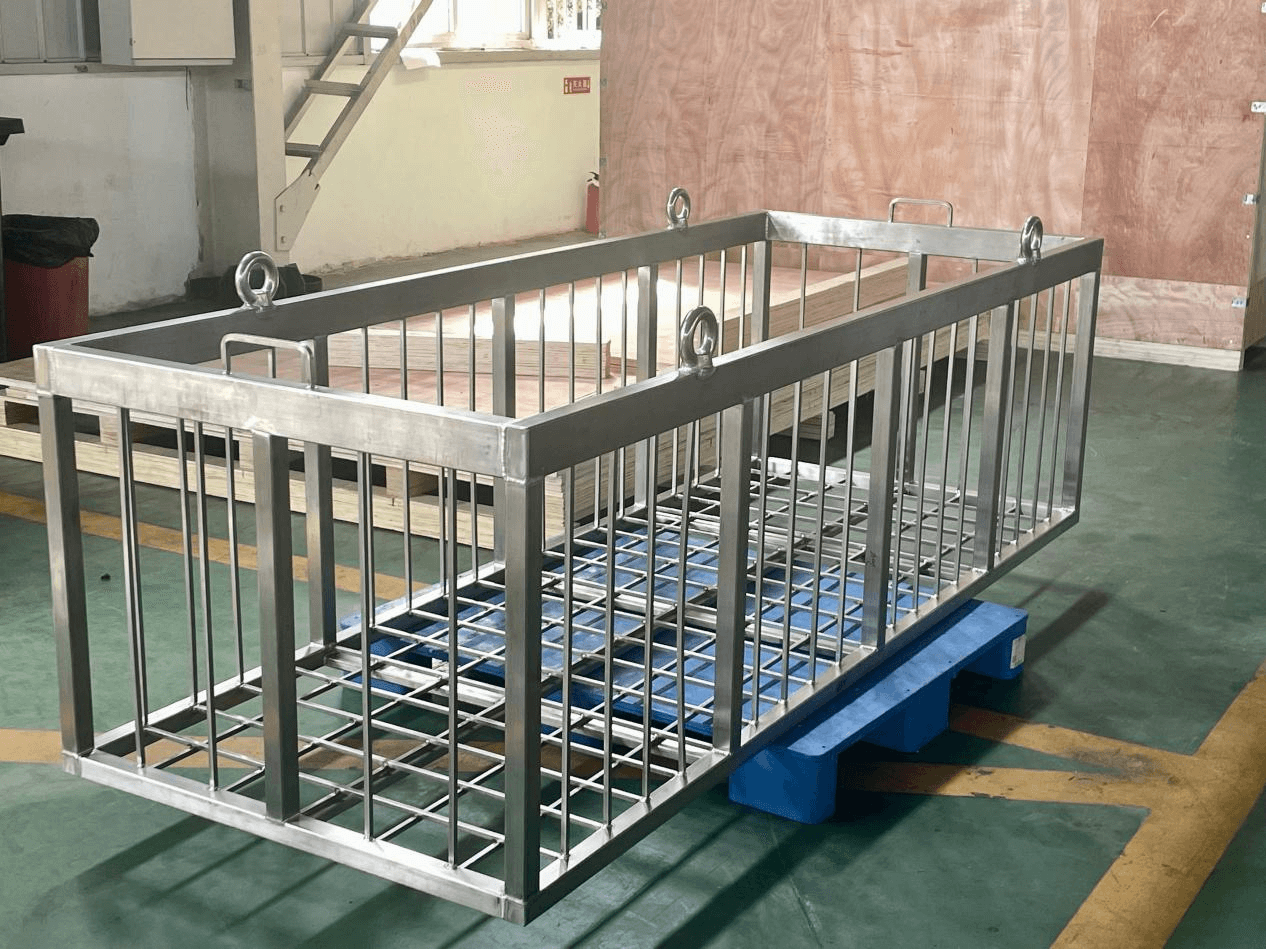

Mochine o na le lintlha tse 'maloa tsa bohlokoa tsa tekheniki:

Tanka e le 'ngoe e nang le bokhoni bo boholo: E etselitsoe ho amohela likarolo tse kholo kapa tse kholo joalo ka li-cylinder blocks, li-brake components, le li-gearbox housings.

Li-transducer tsa ultrasonic tse matla haholo: E netefatsa ho kenella ho tebileng, ho ts'oanang ho lijeometri tse rarahaneng ho tlosa oli, li-deposit tsa carbon, le li-chips tsa tšepe.

Thuso ea moea o phoroselang: E matlafatsa tsitsipano ka har'a mokelikeli o hloekisang bakeng sa ho tlosa litšila hantle.

Sistimi ea ho sefa ea potoloho: E lula e sefa tharollo ea ho hloekisa ho lelefatsa bophelo ba mokelikeli le ho fokotsa litšenyehelo tsa tlhokomelo.

Intelligent control panel: Sebopeho sa ts'ebetso e bohareng bakeng sa mocheso, nako le taolo ea polokeho.

Sebopeho sa modular: E itokiselitse ntlafatso ea nako e tlang kapa ho kopanngoa le ho jarolla ka ho iketsa / ho laolla.

Mochini o loketse ka ho khetheha mehala ea ho etsa likoloi, lithupelo tsa machining, le litsi tsa ho lokisa. E khona ho tlosa litšila tse tloaelehileng tse hlahisoang nakong ea ho itšeha, ho hatakela kapa ho phekola mocheso. Ka ho fokotsa mehato ea ho hloekisa ka letsoho, tsamaiso e thusa bareki ho boloka litšenyehelo tsa basebetsi le ho finyella mokhoa o tsitsitseng le o ka tšeptjoang oa ho hloekisa.

Ho sa tsotellehe ho rarahana ha lisebelisoa tsa thepa, lihlopha tsa boenjiniere tsa TENSE le tsa tlhahiso li ile tsa tiisa ts'ebetso e potlakileng ho tloha ho moralo ho ea pele. Moreki o ananetse boemo bo holimo ba ho itloaetsa, ho ela hloko lintlha, le boitlamo ba linako tsa ho fana.

Ka lisebelisoa tsa ho hloekisa tsa ultrasonic, li-transducers li fetisetsa ho sisinyeha ha mechine e phahameng ka ho fetisisa ka har'a tharollo ea ho hloekisa, ho etsa hore ho be le liphello tsa cavitation ka har'a metsi. Ho thehoa le ho oa ka tšohanyetso ha li-bubble tsa cavitation li lokolla maqhubu a matla a matla a matla, ho tlosa oli, likaroloana le litšila tse nyenyane tse khomarelang holim'a li-workpieces. Melemo ea ts'ebetso ea li-transducers e kenyelletsa karabelo ea khafetsa, matla a ho sebetsana le matla, amplitude, le ts'ebetso ea ho kopanya ha mochini, e khethollang ka kotloloho matla le ho ts'oana ha ts'ebetso ea ho hloekisa.

Mochini ona o moholo o nang le tanka e le 'ngoe ea ho hloekisa ea ultrasonic e na le li-transducers tse 382 tse sebetsang hantle, tse atolosang haholo tšireletso ea matla a ultrasonic le ho ntlafatsa ts'ebetso ea ho hloekisa, ho etsa bonnete ba hore junifomo le ho hloekisoa ka ho feletseng ha sekhutlo se seng le se seng sa lisebelisoa tse kholo, tse rarahaneng.

Sebopeho se loketseng sa marang-rang se tiisa kabo e tšoanang ea matla a ultrasonic ka har'a tanka ea ho hloekisa, ho qoba "libaka tse shoeleng" le libaka tse nang le matla a fokolang, ka hona ho ntlafatsa ts'ebetso ea ho hloekisa ka kakaretso. Li-transducer le tsona li tlameha ho ba le li-network tse tsamaellanang le li-impedance le li-circuits ho ntlafatsa ts'ebetso ea phetolo ea motlakase le ho fokotsa tšebeliso ea matla a sistimi.

Thepa ea ho qetela e se e rometsoe ka sekepe. Video e khutšoane ea ho fana e fumaneha ha u e kopa kapa ka li-platform tsa rona tsa sechaba.

TENSE e ntse e tsoela pele ho sebetsa ka ho khetheha lisebelisoa tse tsoetseng pele tsa ho hloekisa liindasteri tse shebaneng haholo le litharollo tse tobileng bareki. Re amohela balekane ho pholletsa le liindasteri tse fapaneng ho hlahloba lits'ebetso tsa rona tsa ho hloekisa le ho nts'etsapele lisebelisoa tse lokiselitsoeng hammoho.

Haufinyane tjena, TENSE e phethile ka katleho ho fana ka mochine o moholo o entsoeng ka tloaelo o entsoeng ka tanka e le 'ngoe bakeng sa moreki oa indasteri ea likarolo tsa likoloi. Mochine o ne o entsoe ka ho khetheha ho sebetsana le likarolo tse kholo le tse boima tse nang le litlhoko tse phahameng tsa ho hloekisa. Ka mor'a ho feta tlhahlobo e feletseng ea ka hare, thepa e se e rometsoe sebakeng sa bareki.

Ho fapana le litsamaiso tse tloaelehileng tsa ho hloekisa, morero ona o ne o hloka tharollo e sa tloaelehang e lokiselitsoeng tšebetso ea moreki. Sistimi e fanoeng e kopanya ho hloekisa ka matla a matla a ultrasonic ka boits'oaro bo bohlale, e ikemiselitseng ho fokotsa haholo tlhahiso ea basebetsi ha e ntse e ntlafatsa ho hloekisoa ho nepahetseng le ho tsitsa.

Mochini o loketse ka ho khetheha mehala ea ho etsa likoloi, lithupelo tsa machining, le litsi tsa ho lokisa. E khona ho tlosa litšila tse tloaelehileng tse hlahisoang nakong ea ho itšeha, ho hatakela kapa ho phekola mocheso. Ka ho fokotsa mehato ea ho hloekisa ka letsoho, tsamaiso e thusa bareki ho boloka litšenyehelo tsa basebetsi le ho finyella mokhoa o tsitsitseng le o ka tšeptjoang oa ho hloekisa.

Ho sa tsotellehe ho rarahana ha lisebelisoa tsa thepa, lihlopha tsa boenjiniere tsa TENSE le tsa tlhahiso li ile tsa tiisa ts'ebetso e potlakileng ho tloha ho moralo ho ea pele. Moreki o ananetse boemo bo holimo ba ho itloaetsa, ho ela hloko lintlha, le boitlamo ba linako tsa ho fana.

Thepa ea ho qetela e se e rometsoe ka sekepe. Video e khutšoane ea ho fana e fumaneha ha u e kopa kapa ka li-platform tsa rona tsa sechaba.

TENSE e ntse e tsoela pele ho sebetsa ka ho khetheha lisebelisoa tse tsoetseng pele tsa ho hloekisa liindasteri tse shebaneng haholo le litharollo tse tobileng bareki. Re amohela balekane ho pholletsa le liindasteri tse fapaneng ho hlahloba lits'ebetso tsa rona tsa ho hloekisa le ho nts'etsapele lisebelisoa tse lokiselitsoeng hammoho.

Nako ea poso: Jul-25-2025