Ntlafatsa Liphetho tsa ho Hloekisa le ho Eketsa Bophelo ba Lisebelisoa

Lisebelisoa tsa Ultrasonic li sebelisoa haholo libakeng tse fapaneng, ho kenyeletsoa lits'ebetso tsa indasteri, tsa bongaka le tsa malapeng. Ka tšebeliso ea nako e telele, thepa e ka 'na ea e-ba le liphoso kapa ea hloka tlhokomelo, moo ho hlokahalang ho qhaqhoa. Sengoliloeng sena se tla qaqisa mehato ea disassembly le ho fana ka litemoso tse sebetsang ho thusa basebelisi ho qhaqhaultrasonic cleanerka polokeho le ka bokgabane.

1. Mabaka a ho Hlakola Sehloekisi sa Ultrasonic

Pele u kenella ka har'a mehato ea disassembly, ho bohlokoa ho utloisisa hore na ke hobane'ng ha u ka hloka ho qhaqholla sehloekisi sa ultrasonic. Mabaka a tloaelehileng a kenyelletsa:

Ho se sebetse ha Thepa: Joalo ka jenereithara e senyehileng ea ultrasonic, ho se sebetse ha sesebelisoa sa ho futhumatsa, kapa ho lutla ka tanka ea ho hloekisa.

Tlhokomelo ea Kamehla: Ho hloekisa likarolo tsa ka hare, ho nkela likarolo tse tsofetseng (mohlala, litiiso, lintho tse futhumatsang), joalo-joalo.

Lintlafatso: Ho nkela jenereithara ea ultrasonic sebaka ka mohlala o phahameng oa matla kapa ho eketsa ts'ebetso e ncha ho yuniti.

Tlhokomelo ea kamehla le ho qhaqha ke tsa bohlokoa bakeng sa ho netefatsa hore lisebelisoa li sebetsa ka katleho le ho nka nako e telele.

2. Boitokisetso Pele ho Disassembly

①Koala Motlakase 'me Netefatsa Tšireletseho

Pele o harola mochini o hloekisang oa ultrasonic, kamehla khaola phepelo ea motlakase ho netefatsa hore lisebelisoa li tima ka botlalo. Haeba yuniti e sa tsoa sebelisoa, emela hore e pholile ho fihlela mocheso oa kamore ho qoba ho chesa.

② Lokisetsa Lisebelisoa

Lisebelisoa tse tloaelehileng tse hlokahalang bakeng sa ho qhaqhoa li kenyelletsa li-screwdrivers (bobeli Phillips le flathead), li-wrenches, li-pliers, li-tweezers, joalo-joalo Ho itšetlehile ka litlhoko tsa mohlala le ho qhaqha, lisebelisoa tse khethehileng tse kang Wrench ea Allen le tsona li ka 'na tsa hlokahala.

③ Bala Buka ea Mosebelisi

Mefuta le mefuta e fapaneng ea lihloekisi tsa ultrasonic li na le meaho e fapaneng. Ho khothaletsoa haholo ho bala bukana ea mosebelisi ka hloko ho utloisisa sebopeho le lintlha tsa bohlokoa tsa disassembly bakeng sa sesebelisoa sa hau se ikhethileng.

④ Lokisa Lisebelisoa tsa ho Hloekisa

Nakong ea ho qhaqhoa, ho ka 'na ha hlokahala hore u hloekise bokahare ba thepa, kahoo ke khopolo e ntle ho lokisa masela a hloekileng a bonolo, lisebelisoa tsa ho hloekisa le metsi.

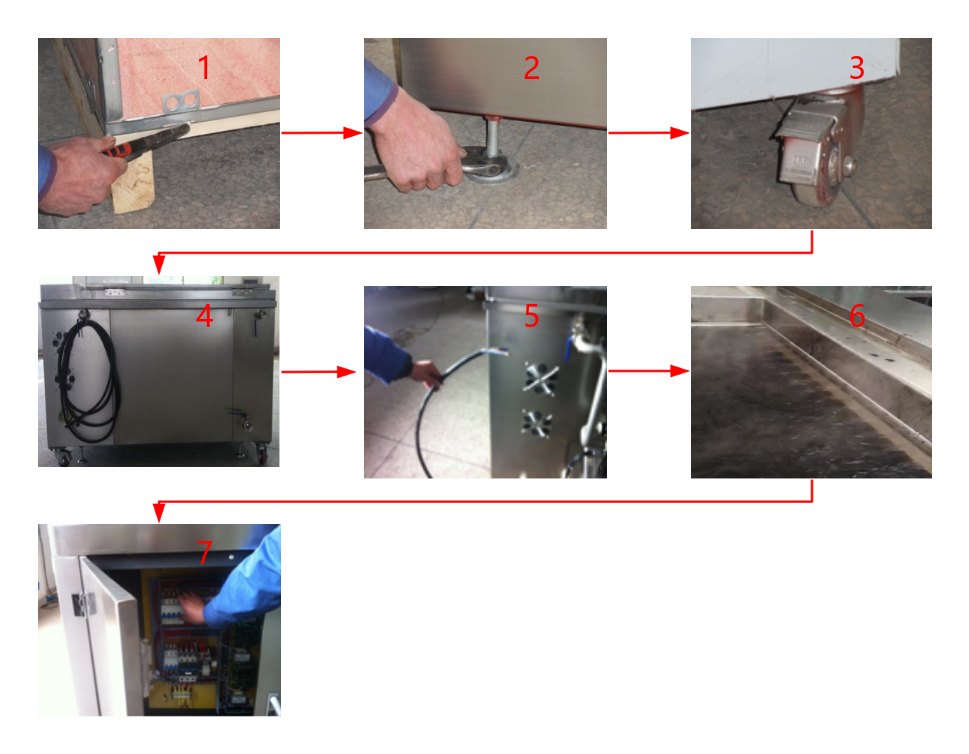

3. Ultrasonic CleanerMehato ea ho qhaqha

① Tlosa Outer Shell

Sebelisa screwdriver ho manolla li-fasteners holim'a khetla e ka ntle 'me ue tlose ka bonolo. Ela hloko hore u se ke ua sebelisa matla a feteletseng ho qoba ho senya khetla e ka ntle kapa likarolo tse ka hare. Haeba khetla e ka ntle e na le likoto, u ka e bula ka bonolo ka pry bar ea polasetiki.

② Tlosa Tanka ea ho Hloekisa

Hangata tanka ea ho hloekisa e sirelelitsoe setsing sa lisebelisoa ka li-screw kapa li-clip. Hlakola li-fasteners kapa u lokolle likotoana, 'me u tlose tanka ea ho hloekisa ka hloko. Haeba tanka ea ho hloekisa e hokahane le jenereithara ea ultrasonic, etsa bonnete ba hore o khaola likhoele tsa khokahano pele.

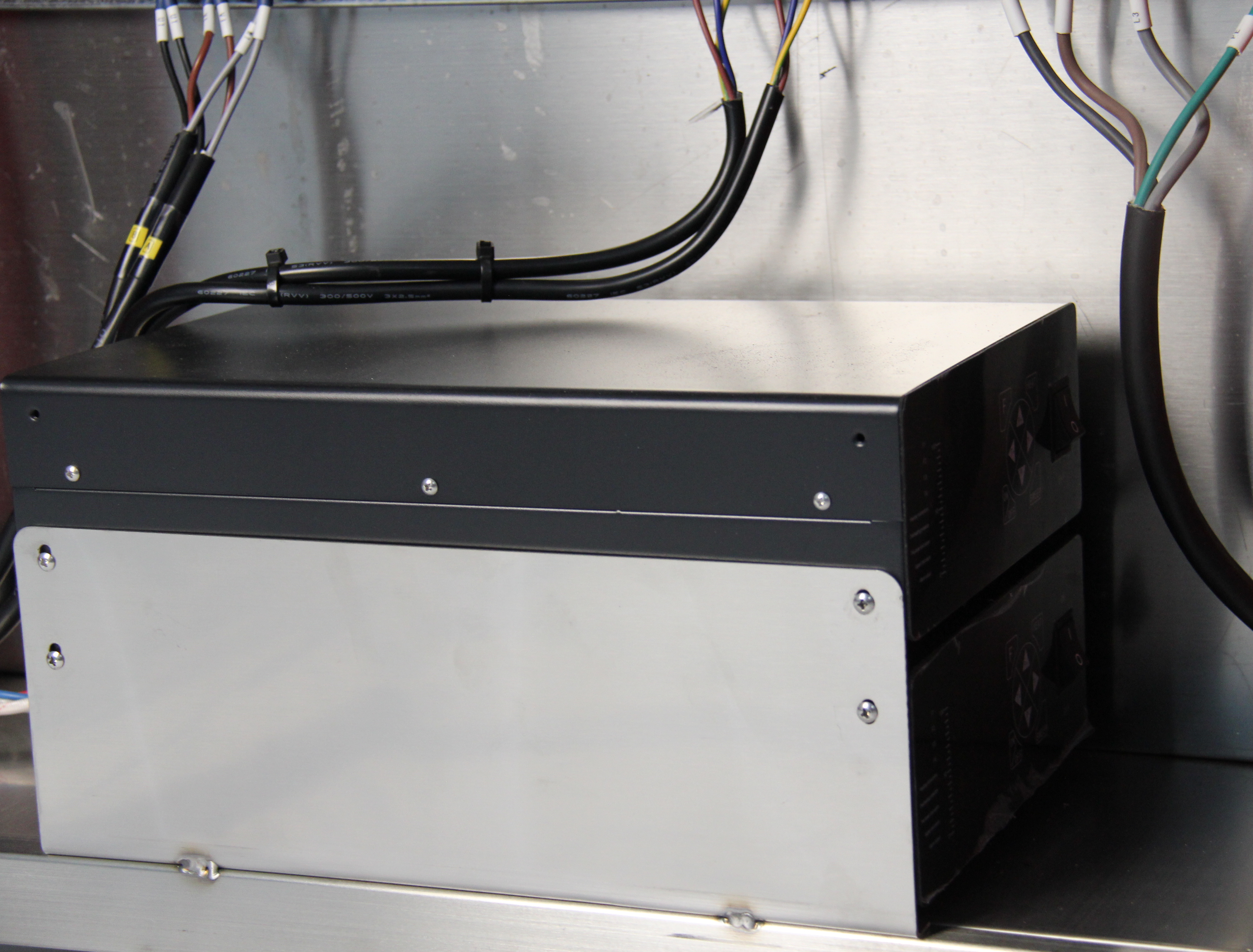

③ Tlosa jenereithara ea Ultrasonic

Jenereithara ea ultrasonic ke karolo ea mantlha ea sesebelisoa mme hangata e kenngoa ka tlase kapa ka lehlakoreng la thepa. Hakolla likhoele tsa motlakase le lipontšo ho jenereithara ea ultrasonic, lokolla li-fasteners, 'me u tlose jenereithara ka hloko.

④ Tlosa Element Heating

Ntho ea ho futhumatsa (mohlala, tube ea ho futhumatsa) hangata e kenngoa ka tlaase kapa ka lehlakoreng la tanka ea ho hloekisa. Hakolla lithapo tsa motlakase, lokolla li-fasteners, 'me ka hloko u tlose ntho ea ho futhumatsa.

⑤ Tlosa Likarolo Tse Ling

Ho itšetlehile ka tlhokahalo, tlosa likarolo tse ling tse kang lisebelisoa tsa mocheso, li-control panel, le lipompo tsa metsi. Nakong ea ho qhaqhoa, ho bohlokoa ho ela hloko boemo le khokahanyo ea karolo ka 'ngoe bakeng sa ho kopanya habonolo hamorao.

4. Tlhahlobo le Tlhokomelo Ka mor'a Disassembly

① Hloekisa ka hare ho Thepa

Sebelisa lesela le hloekileng le bonolo ho hlakola bokahare ba thepa, ho tlosa lerōle le litšila. Haeba ho na le sekala ka har'a tanka ea ho hloekisa kapa liphaephe, u ka sebelisa mochine o khethehileng oa ho hloekisa ho e tlosa.

② Hlahloba Likarolo Tse Aparehang

Lekola boemo ba likarolo tse tloaelehileng tse kang liqibi, li-tubes tse futhumatsang le li-transducer tsa ultrasonic. Haeba likarolo tse ling li senyehile kapa li felile, li khutlise hang hang.

③ Lekola Mosebetsi oa Karolo ka 'ngoe

Pele o kopanya hape, lisebelisoa tsa liteko joalo ka jenereithara ea ultrasonic le lisebelisoa tsa ho futhumatsa ho netefatsa hore li sebetsa hantle.

5. Litlhokomelo Nakong ea Ts'ebetso ea Disassembly

① Qoba ho Senya Likarolo Tsa ka Hare

E-ba bonolo ha u qhaqha ho qoba ho sebelisa matla a feteletseng a ka senyang likarolo. Ela hloko haholoanyane ha u sebetsana le lisebelisoa tse bobebe, tse kang transducer ea ultrasonic.

② Rekota Mehato ea ho qhaqha

Ho khothaletsoa ho nka linepe kapa lintlha tsa mohato o mong le o mong oa ho qhaqha ho thusa ka ho kopanya hape hamorao. Bakeng sa likhoele le likurufu, nahana ka ho li tšoaea ho thibela pherekano.

③ Tšireletseho ea Motlakase

Netefatsa hore lisebelisoa lia tima ha u qhaqha likarolo tsa motlakase, 'me u qobe ho tšoara lithapo tse pepenene. Haeba u sa tloaelane le mosebetsi oa motlakase, ho bohlokoa ho batla thuso ea litsebi.

④ Latela Buka ea Mosebelisi

Kaha mefuta e fapaneng ea li-ultrasonic cleaners e ka 'na ea fapana ka sebopeho, kamehla latela litaelo tse bukeng ea mosebedisi bakeng sa disassembly e nepahetseng.

6. Mathata a Tloaelehileng le Litharollo

① Li-Screw tse thata

Haeba li-screw li rusitse 'me ho le thata ho li tlosa, sebelisa marotholi a seng makae a mafura 'me u eme metsotso e seng mekae pele u leka hape. Haeba screw e senyehile, u ka sebelisa screw extractor ho e tlosa.

② Bothata ba ho Hakolla Lithapo

Sebelisa li-tweezers kapa screwdriver e nyane ho bula likotoana tsa cable ka bonolo, ho qoba ho hula likhoele, tse ka bakang tšenyo.

③ Bothata ba ho Kopanya hape ka mor'a ho qhaqha

Haeba u kopana le mathata ha u ntse u kopanya hape, sheba linepe kapa lintlha tse nkiloeng nakong ea disassembly ho netefatsa hore karolo ka 'ngoe e behiloe hantle.

7. Qetello

Ho qhaqha mochine o hloekisang oa ultrasonic ho hloka tlhokomelo e hlokolosi le mamello. Ka ho latela mehato le litemoso tse boletsoeng tataisong ena, basebelisi ba ka etsa mesebetsi ea disassembly ka mokhoa o sireletsehileng le ka katleho. Ebang ke bakeng sa ho lokisa, ho lokisa, kapa ho ntlafatsa, ho utloisisa mokhoa o nepahetseng oa ho qhaqhoa ke habohlokoa bakeng sa ho netefatsa hore thepa e tsoela pele ho sebetsa ka katleho.

Bakeng sa tlhaiso-leseling e batsi ka li-ultrasonic cleaners, malebela a tlhokomelo, le lintlha tsa sehlahisoa, ka kopo etela [Leqephe la Sehlahisoa sa Ultrasonic] ho ithuta haholoanyane ka tharollo le lits'ebeletso tsa rona.

Nako ea poso: May-08-2025