Phakathi kwazo zonke iindlela zokucoca zangoku, ukucocwa kwe-ultrasonic yeyona nto isebenzayo kwaye isebenzayo.Isizathu sokuba kutheni ukucocwa kwe-ultrasonic kunokufezekisa umphumo onjalo kuhambelana ngokusondeleyo nomgaqo wayo okhethekileyo wokusebenza kunye nendlela yokucoca.Iindlela eziqhelekileyo zokucoca ngesandla ngokungathandabuzekiyo azikwazi ukuhlangabezana neemfuno.Nokuba ukucocwa komphunga kunye nokucoca ijethi yamanzi enoxinzelelo oluphezulu akunakuhlangabezana nemfuno yokucoceka okuphezulu.Ke ngoko, esi sizathu sokuba ukucocwa kwe-ultrasonic kusetyenziswa ngakumbi kumashishini ahlukeneyo.

Iindawo zokusetyenziswa kokucoca nge-ultrasonic:

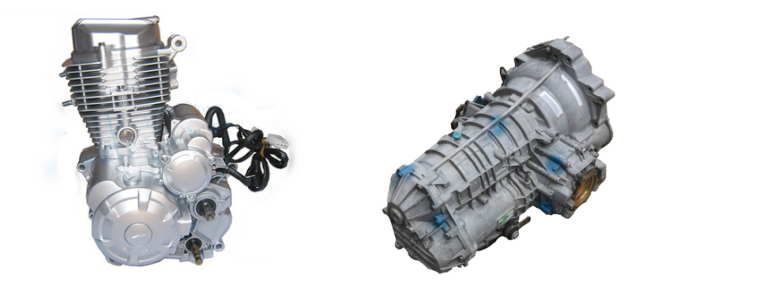

1. Ishishini loomatshini: ukususwa kwegrisi echasene nomhlwa;ukucocwa kwezixhobo zokulinganisa kunye nezixhobo zokusika;ukususwa kwegrisi kunye nokugqwala kwamalungu omatshini;ukucocwa kwee-injini, ii-carburetors kunye ne-auto parts, i-dredging kunye nokucoca izihlungi kunye nezikrini, njl.

2. Umzi-mveliso wonyango womphezulu: ukususwa kwegrisi kunye nokususwa komhlwa phambi kwe-electroplating;ukucoca phambi kokufakwa kwe-ion;unyango lwe-phosphating;ukususa iidiphozithi zekhabhoni, isikali se-oxide, i-polish paste, unyango lokuvula umphezulu wezinto zokusebenza zetsimbi, njl.

3. Ishishini lezonyango: ukucoca, ukubulawa kweentsholongwane, ukuvala inzalo yezixhobo zonyango, ukucocwa kwezixhobo zebhubhoratri, njl.

4. Ishishini lezixhobo: ukucoceka okuphezulu kokucocwa kweengxenye ezichanekileyo, ukucoca ngaphambi kokuhlanganisana, njl.

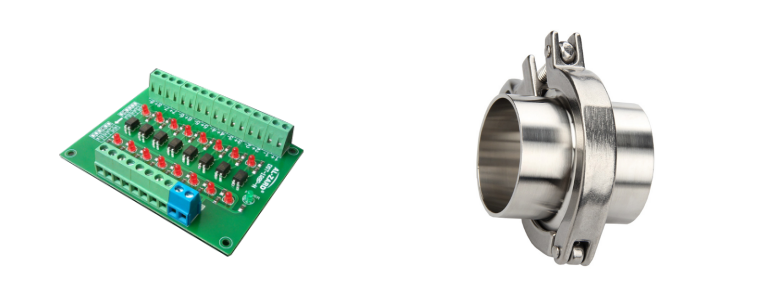

5. Imboni ye-Electromechanical kunye ne-elektroniki: ukususwa kwe-rosin kunye ne-welding spots kwiibhodi zeesekethe eziprintiweyo;ukucocwa koqhagamshelwano lwe-high-voltage, iitheminali kunye nezinye iindawo zomatshini kunye ne-elektroniki, njl.

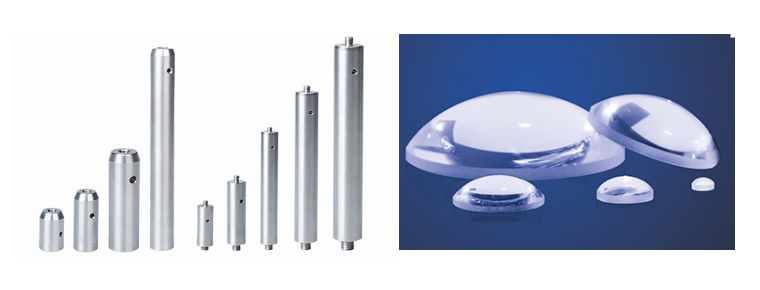

6. Imboni ye-Optical: i-degreasing, ukubila, ukususa uthuli kunye nokunye kwizixhobo ezibonakalayo.

7. Ishishini le-semiconductor: ukucoceka okuphezulu kokucocwa kwee-wafers ze-semiconductor.

8. ISayensi, imfundo kunye nenkcubeko: ukucocwa kunye nokwehliswa kwezixhobo zaselabhoratri ezifana nekhemistri kunye nebhayoloji.

9. Iiwotshi kunye nobucwebe: susa i-sludge, uthuli, i-oxide layer, i-polish paste, njl.

10. Ishishini le-Petrochemical: ukucocwa kunye nokuchithwa kweefilitha zetsimbi;ukucocwa kwezikhongozeli zeekhemikhali, abatshintshisi, njl.

11. Ishishini lokuprinta i-textile kunye nokudaya: ukucoca i-spindles ye-textile, i-spinnerets, njl.

12. Abanye: Ukucocwa kwe-ultrasonic: susa izinto ezingcolileyo, udilize imingxuma emincinci, njengokucoca izitywina, ukubuyiselwa kwe-antique, kunye nokuchithwa kwemibhobho yombane yemoto.

Ukuvuselela i-ultrasonic: ukukhawuleza ukuchithwa, ukuphucula ukufana, ukukhawulezisa ukuphendulwa komzimba kunye neekhemikhali, ukuthintela ukubola, ukukhawulezisa i-oil-water emulsification, njengokuxuba idayi ye-solvent, i-ultrasonic phosphating, njl.

I-Ultrasonic coagulation: imvula ekhawulezileyo kunye nokwahlula, njengokujikeleza kwembewu, ukususwa kwe-slag yesiselo, njl.

I-Ultrasonic sterilization: bulala iibhaktheriya kunye nokungcola kwezinto eziphilayo, ezifana nokunyangwa kwamanzi amdaka, ukuchithwa kwegesi, njl.

I-ultrasonic pulverization: ukunciphisa ubungakanani be-particle ye-solute, njenge-cell pulverization, uvavanyo lweekhemikhali, njl.

Ukutywinwa kwe-Ultrasonic: Ukuphelisa igesi ye-interstitial kunye nokwandisa ukuxinana ngokubanzi, njengepeyinti yokudipha.

Ixesha lokuposa: Jun-22-2021