Ntawm tag nrho cov kev tu tam sim no, kev tu ultrasonic yog qhov ua tau zoo tshaj plaws thiab muaj txiaj ntsig zoo.Yog vim li cas vim li cas ultrasonic tu tuaj yeem ua tiav cov txiaj ntsig zoo li no rau nws txoj kev ua haujlwm tshwj xeeb thiab kev tu.Cov txheej txheem kev ntxuav ntawm phau ntawv txhais tau tias tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua.Txawm tias chav ntxhua khaub ncaws thiab lub tshuab nqus dej siab siab tuaj yeem ua tsis tau raws li qhov kev thov kom huv dua.Yog li ntawd, qhov no yog vim li cas vim li cas ultrasonic tu yog nce siv nyob rau hauv ntau yam lag luam.

Daim ntawv thov thaj chaw ntawm ultrasonic tu:

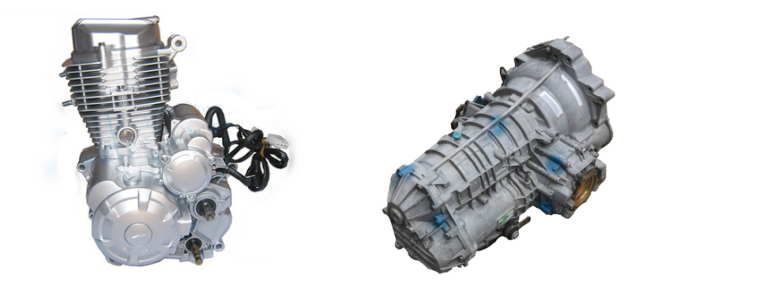

1. Machinery kev lag luam: tshem tawm cov roj los tiv thaiv xeb;ntxuav cov cuab yeej ntsuas thiab cov cuab yeej txiav;degreasing thiab xeb tshem tawm ntawm txhua yam khoom;tu lub cav, carburetor thiab nws pib qhov chaw, dredging thiab tu cov ntxaij lim dej thiab cov ntxaij vab tshaus, thiab lwm yam.

2. Kev kho deg kev lag luam: degreasing thiab xeb tshem tawm ua ntej electroplating;ntxuav ua ntej ion plating;phosphating kev kho mob;tshem tawm cov pa roj carbon deposits, oxide nplai, polishing paste, deg ua kom kho cov hlau workpieces, thiab lwm yam.

3. Kev lag luam kev kho mob: ntxuav, tshuaj tua kab mob, ua kom tsis muaj menyuam ntawm cov khoom siv kho mob, ntxuav cov khoom siv hauv chav kuaj, thiab lwm yam.

4. Instrumentation kev lag luam: siab huv tu ntawm precision qhov chaw, ntxuav ua ntej sib dhos, thiab lwm yam.

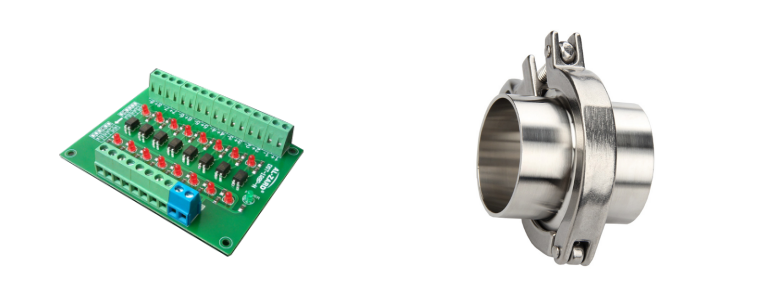

5. Electromechanical thiab hluav taws xob kev lag luam: kev tshem tawm rosin thiab vuam chaw ntawm cov ntawv luam tawm Circuit Board;kev ntxuav ntawm high-voltage contacts, terminals thiab lwm yam khoom siv hluav taws xob thiab hluav taws xob, thiab lwm yam.

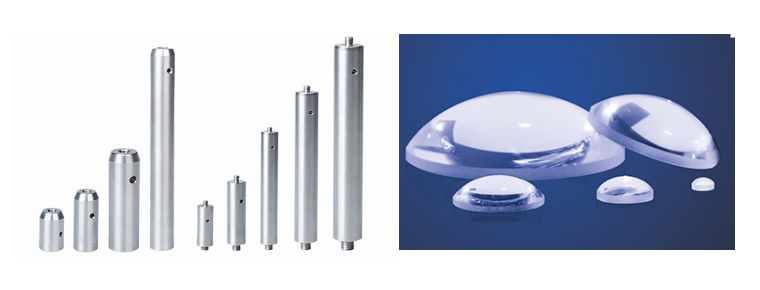

6. Kev lag luam kho qhov muag: degreasing, tawm hws, tshem tawm plua plav thiab lwm yam khoom siv kho qhov muag.

7. Kev lag luam semiconductor: kev ua kom huv huv siab ntawm cov khoom siv hluav taws xob semiconductor wafers.

8. Kev tshawb fawb, kev kawm thiab kab lis kev cai: ntxuav thiab tshem tawm cov khoom siv hauv chav kuaj xws li chemistry thiab biology.

9. Watches thiab hniav nyiaj hniav kub: tshem tawm sludge, plua plav, oxide txheej, polishing muab tshuaj txhuam, thiab lwm yam.

10. Petrochemical kev lag luam: tu thiab dredging ntawm hlau lim;ntxuav cov ntim tshuaj, exchangers, thiab lwm yam.

11. Textile printing thiab dyeing kev lag luam: tu textile spindles, spinnerets, thiab lwm yam.

12. Lwm tus: Ultrasonic tu: tshem tawm cov pa phem, khawb qhov me me, xws li ntxuav cov ntsaws ruaj ruaj, kev kho vaj tse qub qub, thiab dredging ntawm lub tsheb fais fab nozzles.

Ultrasonic nplawm: ua kom tawg, txhim kho uniformity, ua kom lub cev thiab tshuaj lom neeg muaj zog, tiv thaiv dhau-corrosion, ceev roj-dej emulsification, xws li hnyav dye mixing, ultrasonic phosphating, thiab lwm yam.

Ultrasonic coagulation: ceev los nag thiab kev sib cais, xws li cov noob flotation, haus slag tshem tawm, thiab lwm yam.

Ultrasonic sterilization: tua cov kab mob thiab cov organic pollutants, xws li dej phwj kho, degassing, thiab lwm yam.

Ultrasonic pulverization: txo qhov me me ntawm cov kua nplaum, xws li cell pulverization, tshuaj ntsuam xyuas, thiab lwm yam.

Ultrasonic sealing: Tshem tawm cov pa nruab nrab thiab ua kom tag nrho qhov ntom ntom, xws li dipping xim.

Post lub sij hawm: Jun-22-2021