Har'a mekhoa eohle ea hona joale ea ho hloekisa, ho hloekisa ka ultrasonic ke eona e sebetsang ka ho fetisisa le e sebetsang ka ho fetisisa.Lebaka leo ka lona ho hloekisa ka ultrasonic ho ka finyellang phello e joalo ho amana haufi-ufi le molao-motheo oa eona o ikhethang oa ho sebetsa le mokhoa oa ho hloekisa.Mekhoa e tloaelehileng ea ho hloekisa ka letsoho ntle le pelaelo e ke ke ea finyella litlhoko.Esita le ho hloekisa mouoane le ho hloekisa jete ea metsi ka khatello e phahameng ho ke ke ha finyella tlhokahalo ea bohloeki bo phahameng.Ka hona, ke lona lebaka le etsang hore ho hloekisoa ha ultrasonic ho sebelisoa haholo liindastering tse fapaneng.

Lisebelisoa tsa ho hloekisa ka ultrasonic:

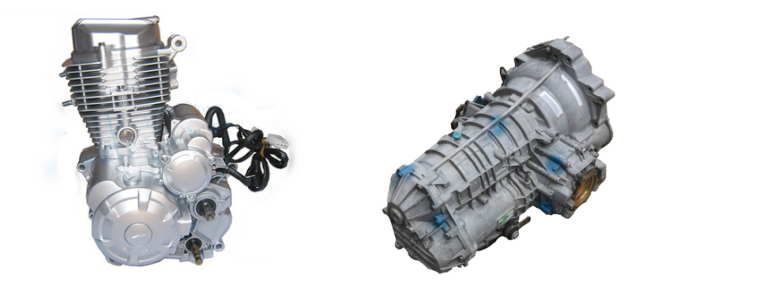

1. Indasteri ea mechine: ho tlosoa ha mafura a khahlanong le mafome;ho hloekisa lisebelisoa tsa ho lekanya le lisebelisoa tsa ho itšeha;degreasing le mafome ho tlosoa ha likarolo tsa mechine;ho hloekisa lienjineri, li-carburetor le likarolo tsa koloi, ho phunya le ho hloekisa li-filters le li-skrini, joalo-joalo.

2. Indasteri ea phekolo ea sefahleho: ho senya le ho tlosoa ha mafome pele ho electroplating;ho hloekisa pele ho ion plating;phekolo ea phosphating;ho tlosa carbon deposits, oxide scale, polishing peste, surface activation treatment ea metal workpieces, joalo-joalo.

3. Indasteri ea bongaka: ho hloekisa, ho thibela likokoana-hloko, sterilization ea lisebelisoa tsa bongaka, ho hloekisa lisebelisoa tsa laboratori, joalo-joalo.

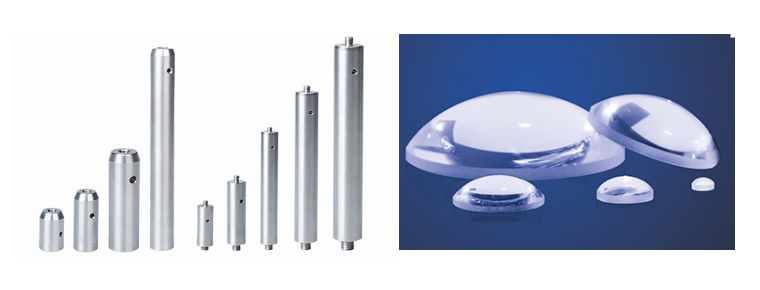

4. Indasteri ea lisebelisoa: bohloeki bo phahameng ba ho hloekisa likarolo tse nepahetseng, ho hloekisa pele ho kopano, joalo-joalo.

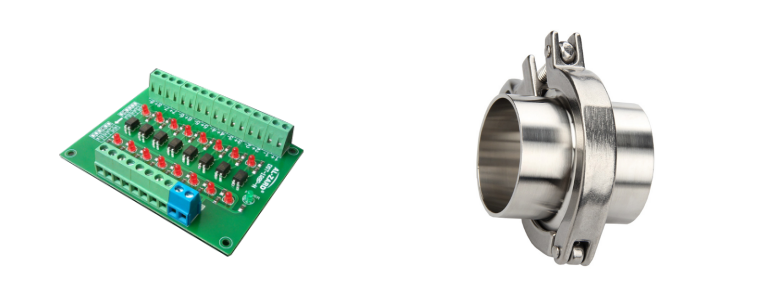

5. Indasteri ea motlakase le ea elektronike: ho tlosoa ha rosin le matheba a welding holim'a liboto tsa potoloho tse hatisitsoeng;ho hloekisoa ha likhokahano tse nang le matla a phahameng a motlakase, li-terminals le likarolo tse ling tsa mochini le tsa elektroniki, joalo-joalo.

6. Indasteri ea optical: ho senya, ho fufuleloa, ho tlosa lerōle joalo-joalo bakeng sa lisebelisoa tsa optical.

7. Indasteri ea semiconductor: tlhoekiso e phahameng ea bohloeki ba liphaephe tsa semiconductor.

8. Saense, thuto le setso: ho hloekisa le ho theola lisebelisoa tsa laboratori tse kang k'hemistri le biology.

9. Lioache le mabenyane: tlosa seretse, lerōle, lera la oxide, pente ea polishing, joalo-joalo.

10. Indasteri ea lik'hemik'hale tsa peterole: ho hloekisa le ho chesoa ha li-filters tsa tšepe;ho hloekisa lijana tsa lik'hemik'hale, li-exchangers, joalo-joalo.

11. Indasteri ea khatiso ea masela le ho daea: ho hloekisa li-spindle tsa masela, li-spinnerets, joalo-joalo.

12. Tse ling: Ho hloekisa ka mokhoa oa Ultrasonic: tlosa lintho tse silafatsang, cheka masoba a manyane, joalo ka ho hloekisa litiiso, ho khutlisa lintho tsa khale, le ho phunya li-nozzle tsa motlakase oa koloi.

Ultrasonic e susumetsang: potlakisa ho qhibiliha, ho ntlafatsa ho tšoana, ho potlakisa liketso tsa 'mele le lik'hemik'hale, ho thibela ho senyeha ho feteletseng, ho potlakisa emulsification ea metsi, e kang ho kopanya dae ea solvent, ultrasonic phosphating, joalo-joalo.

Ultrasonic coagulation: ho potlakisa pula le karohano, joalo ka ho phaphamala ha peo, ho tlosoa ha slag ea seno, joalo-joalo.

Ultrasonic sterilization: bolaea libaktheria le lintho tse silafatsang tsa lintho tse phelang, tse kang ho hloekisa likhoerekhoere, ho senya, joalo-joalo.

Ultrasonic pulverization: fokotsa boholo ba karoloana ea solute, joalo ka cell pulverization, tlhahlobo ea lik'hemik'hale, jj.

Ho tiisoa ha Ultrasonic: Tlosa khase e kenang lipakeng 'me u eketse letsoalo ka kakaretso, joalo ka pente ea ho qoela.

Nako ea poso: Jun-22-2021