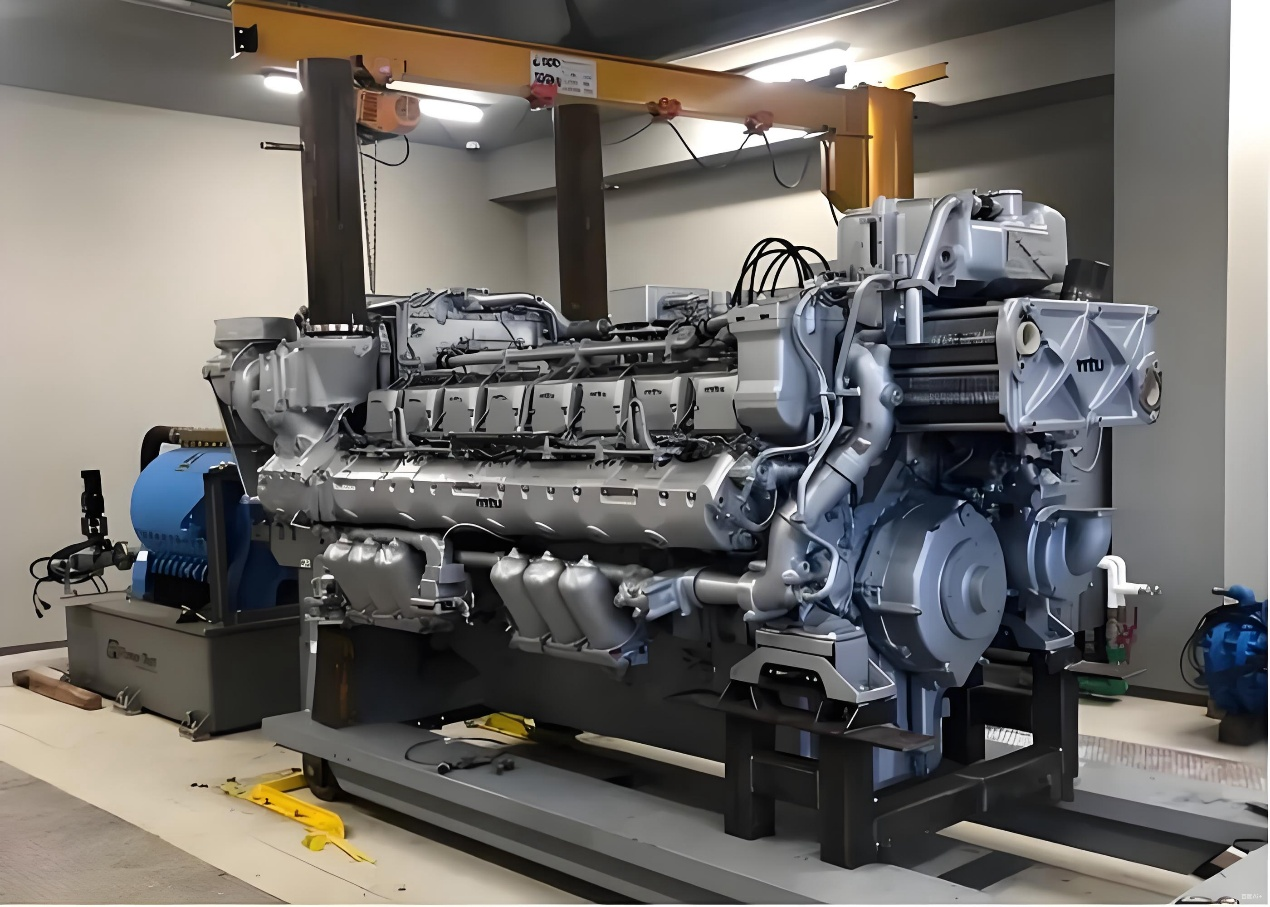

In the maintenance of powertrains of vehicles, ships, or heavy machinery, engine maintenance is of vital importance. Technical professionals rely on various specialized maintenance tools, facilities, and high-performance testing tools to restore the performance of the engine. They conduct professional operations under strict standards. During the disassembly and assembly of the total components, the cleanliness of the parts significantly affects the quality of the maintenance and the progress of subsequent performance testing. The application of cleaning equipment in the cleaning workshop reflects the professional level and technology of the maintenance enterprise.

The engine maintenance and cleaning workshop is a high-tech workplace integrating modern equipment, professional technical standards and strict process procedures. It is like an “advanced operating room” for engines. Through a set of scientific and systematic “washing, examination, treatment and rehabilitation” procedures, tired or damaged engines can be rejuvenated. Cleaning is the prerequisite for precise detection and maintenance; only on a “clean” basis can “precise” maintenance be achieved.

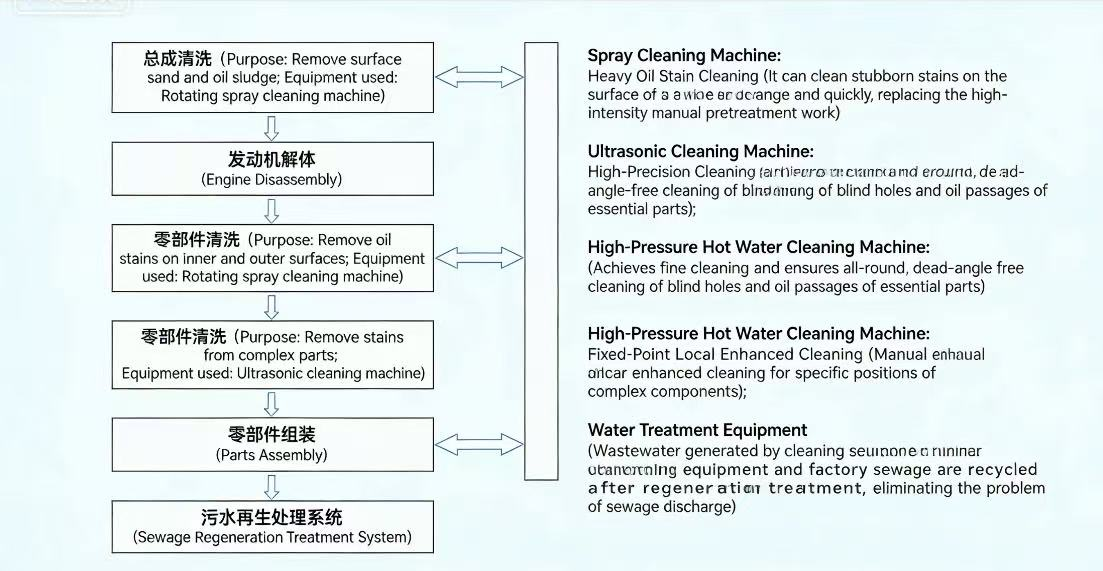

The engine maintenance and cleaning workshop for the power assembly requires several cleaning sections: Before disassembling the assembly, an external cleaning is needed to remove a wide range of surface dirt; after disassembly, cleaning of oil stains and carbon deposits is required; after classification is completed, necessary pre-cleaning is carried out before the necessary tests; before assembly, further fine cleaning and assembly of components is conducted. In summary, it requires: high-pressure cleaning machines, spray cleaning machines, ultrasonic cleaning machines, as well as subsequent sewage treatment equipment, to complete the entire process of pre-treatment, rough cleaning to fine cleaning of components.

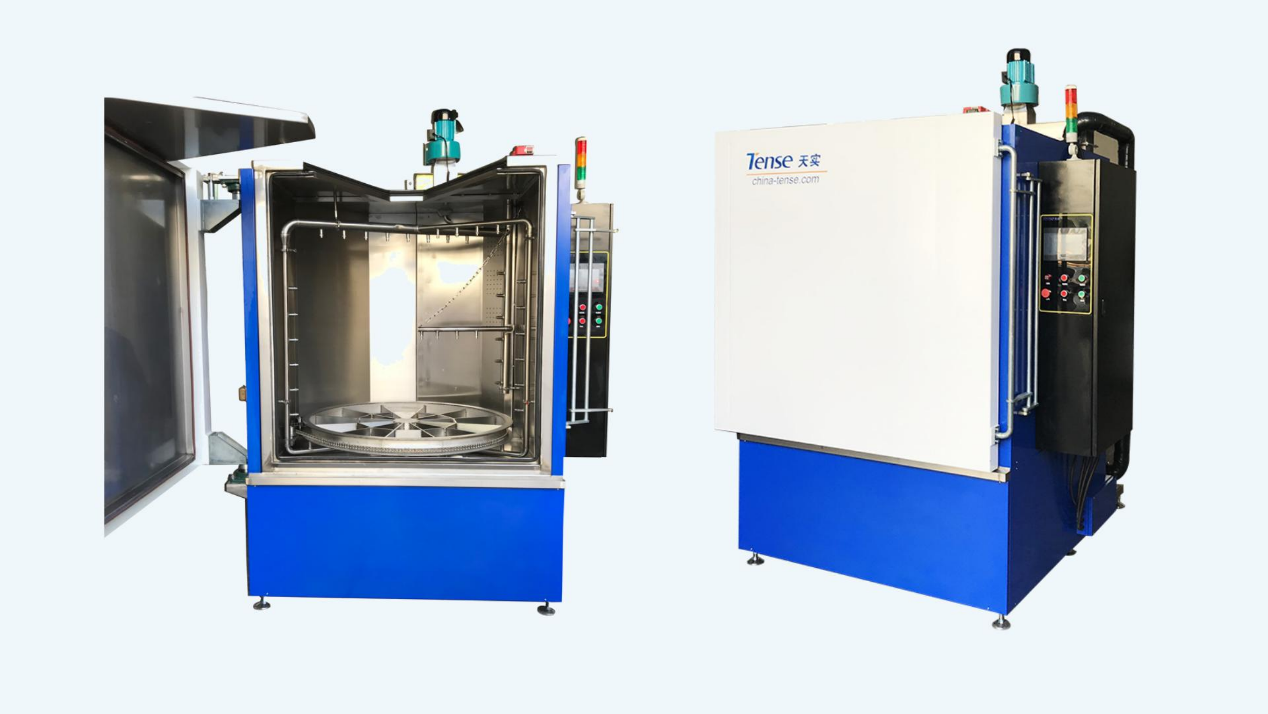

The rotary spray cleaning machine is used for rapid and efficient cleaning of heavy oil stains and oil sludge on surfaces. The entire machine is centrally controlled by PLC, and all working parameters are set through the touch screen. The operator places the parts to be cleaned on the rotating tray using the lifting tool. The spray pipes are arranged in multiple directions. After the manual door is closed, the equipment enters the cleaning state. The rotating tray can rotate 360 degrees. Within the set time, the parts are rinsed, and a completion status indication is given; the cleaning liquid is recycled.

The oscillating ultrasonic cleaning machine is used for high-precision cleaning of oil stains and carbon deposits on components. The entire machine is centrally controlled by PLC, and all working parameters are set through the touch LCD screen. The operator places the components on the material tray by hoisting the equipment and starts the cleaning device with one click. The components automatically descend and sink into the water solution in the tank; during the cleaning process, the pneumatic lifting device moves up and down to reduce cleaning dead zones. After the cleaning is completed, the components automatically rise out of the water surface, completing a complete cleaning process.

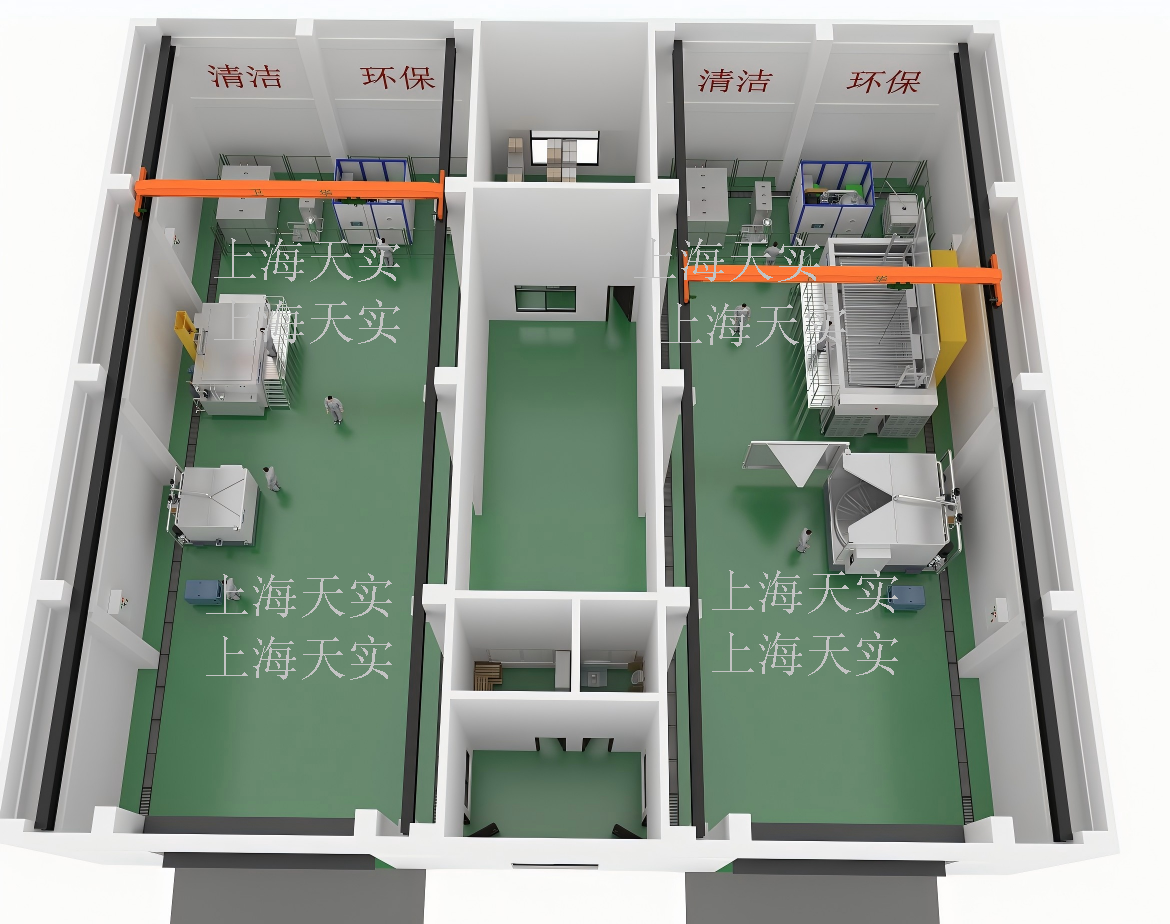

Shanghai Tense was established in 2005. It is mainly engaged in the production, manufacturing and sales of cleaning equipment and sewage treatment equipment. The products include: ultrasonic cleaning machines, spray cleaning machines, high-pressure cleaning machines, water treatment equipment. The cleaning products are widely used in aerospace, mechanical manufacturing, ship docks, railways, casting, chemical industry, metallurgy, engineering machinery, and engine, gearbox, hydraulic components and other parts of machinery in the mining and industrial sectors for high-precision and rapid cleaning of heavy oil-contaminated parts.

Post time: Dec-02-2025