Products

-

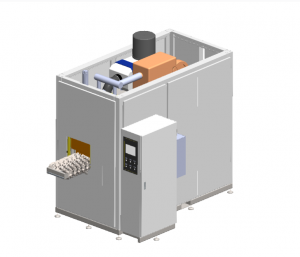

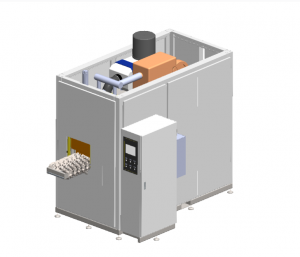

Industrial Cabinet Parts Washers TS-P Series

The TS-P series industrial cabinet parts washer is a simplified and lightweight design based on the TS-L-WP series. The operator places the parts on the cleaning cabinet platform and starts up.

During the cleaning process, the basket is driven by the motor to rotate 360 degrees, and the stainless steel nozzles installed in multiple directions are sprayed to wash the parts; the cleaning work is completed within the set time, and the parts can be manually removed by opening the door. The cleaning medium in the tank can be recycled.

-

Digital Control Ultrasonic Cleaner

Tense industrial cleaning equipment factory was established in 2005; our cleaning equipment has passed ISO9001 quality system certification, EU CE, ROHS certification. Our cleaning equipment is exported to many countries, and has a long-term cooperative relationship with well-known brands such as Bosch , Caterpillar; Komatsu and other enterprises.

-

Lift Ultrasonic Cleaner TS-UD Series

The industry standard range of ultrasonic cleaning equipment ranges from 140 to 2300 liters capacity. They are designed for cleaning and descaling of all types of parts, components and accessories.

All equipment in this line can incorporate a lifting platform that facilitates loading and unloading of parts. They can also carry systems of filtration, separation of oils and water treatments, among others. -

Ultrasonic cleaner TS series

TS series has been specifically designed for the cleaning and degreasing of all type of parts and components in Automotive industry. It achieves excellent cleaning results in many types of materials, especially in complex parts, where the ultrasounds have excellent results thanks to its high penetration capacity. Thus, the results while cleaning automobile engines are spectacular, even in those smaller and delicate parts.

Our Automotive series uses 28 kHz frequency with which the best results for the Automotive Sector are achieved.

-

Combined Lifting Type Ultrasonic Cleaning Machine

Combined lifting type ultrasonic cleaning machine

The equipment is based on the company’s standard model TS-UD series to do the combination of functions to upgrade, so as to meet the streamlined production operations.

-

Mechanical Control Ultrasonic Cleaning Machine

Ultrasonic cleaning is extremely effective at removing dirt and grime—even in the smallest of crevices. It’s high-performance cleaning that cleans your parts faster and cheaper than the alternatives.The equipment volume ranges from 2 liters to 30 liters. If you need a larger volume cleaning machine, please check other catalogs.

-

Automatic parts washing machine (TS-MF)

The TS-MF series automatic parts cleaning machine realizes the functions of ultrasonic cleaning, spray cleaning, bubbling cleaning and hot air drying through a studio; the equipment can cooperate with other automatic equipment to realize unattended and flow production. As an independent cleaning system, the equipment has the characteristics of small footprint and high integration compared with ordinary automatic cleaning machines; because the cleaning process can realize online filtration, this series of cleaning machines has high cleanliness and long service life of cleaning media. specialty. The material can enter the cleaning studio manually (or automatically) through the tooling, the door is automatically closed and locked, the cleaning machine starts to run according to the set program, and the tooling basket can rotate, swing or remain stationary during the cleaning process; the cleaning machine is cleaned and rinsed. , After drying, the door is automatically opened, and the tooling is manually and (or automatically) removed to complete a cleaning process. It is particularly pointed out that because the washing machine material basket has a turning function, it is especially suitable for cleaning and drying shell parts.

-

Spray Cleaning Machine TS-L-WP Series

TS-L-WP series spray cleaners are mainly used for surface cleaning of heavy parts. The operator puts the parts to be cleaned into the cleaning platform of the studio through the hoisting tool (self-provided), after confirming that the parts do not exceed the working range of the platform, close the protective door, and start the cleaning with one key. During the cleaning process, the cleaning platform rotates 360 degrees driven by the motor, the spray pump extracts the cleaning tank liquid to wash the parts at multiple angles, and the rinsed liquid is filtered and reused; The fan will extract the hot air; finally, the end command is issued, the operator will open the door and take out the parts to complete the entire cleaning process.