Industry Application Background

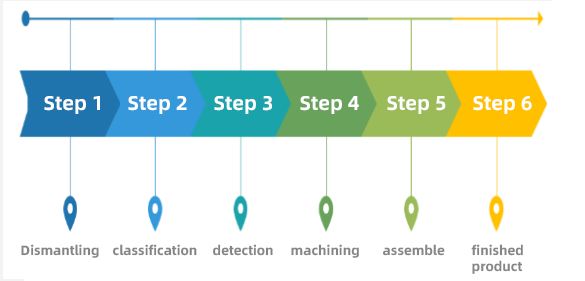

The cleaning process runs through the entire remanufacturing production process (cleaning before disassembly, cleaning before inspection, cleaning after processing, and cleaning before assembly). According to the workpiece characteristics of the remanufactured products and the purpose of the processing process, it is very important to select the appropriate cleaning equipment. Engine remanufacturing, gearbox remanufacturing, turbocharger remanufacturing, motor and generator remanufacturing all involve professional cleaning equipment.

A complete cleaning system ensures the processing quality of the production process. A scientific and reasonable system design not only considers the cleaning results, but also needs to consider the continuity of production, convenience of operation, green emissions and economy.

Case Study

Background:

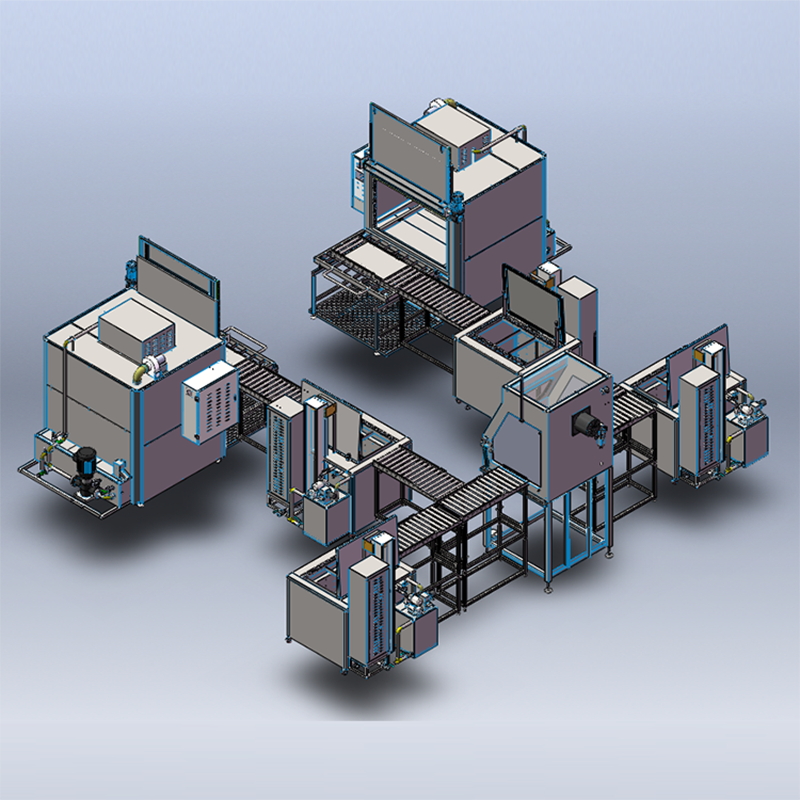

A small-scale high-end engine remanufacturing factory, the factory area is limited. In addition to the cleaning process before disassembly, centralized cleaning is required (cleaning before inspection, after processing, and before assembly)

Solution:

Separate the cleaning process before testing and the cleaning process before processing and assembly to avoid unnecessary secondary contamination. Choose the appropriate treatment process according to the material of the product.

Select the appropriate model based on the physical size and output characteristics of the product.

Choose a reasonable layout and process transfer plan based on the size and characteristics of the site.

Cleaning After Disassembly: Push-in spray cleaning (main purpose: quickly clean oil stains on the surface of the workpiece) → 2 Group throwing ultrasonic cleaning (cleaning the remaining oil on the internal and external surfaces, the most important thing is to clean the carbon deposits) → Manual inspection and cleaning (through this process, the cleaning parts that have not been completed by the cleaning machine are effectively cleaned, and excess residual water is blown away) → Hot air drying (improves anti-rust effect, suitable for storage)

Post-Processing/Pre-Assembly Cleaning: Push-in spray cleaning (remove aluminum/iron chips and oil stains during processing) → 1 Group throwing ultrasonic cleaning (improves cleaning effect) → Manual inspection and cleaning (clean the residue once and remove the water on the surface and inside) → Hot air drying (required for assembly process)

Among them, manual inspection cleaning and hot air drying are shared in two independent processes.

Our Projects

Typical Customers