In industrial maintenance, remanufacturing, and heavy equipment servicing, effective cleaning is a critical step that directly impacts product quality, service life, and operational reliability. Components such as cast iron engine blocks are exposed to extreme operating conditions, resulting in heavy carbon deposits, oil sludge, metal particles, and corrosion residues. Traditional cleaning methods often struggle to reach internal oil channels, blind holes, and complex geometries. This is where the ultrasonic cleaning machine has become an indispensable industrial solution.

Among various operating parameters, ultrasonic frequency plays a decisive role in cleaning performance. For heavy-duty applications, 28kHz has emerged as the industry-preferred frequency and is widely recognized as the gold standard for cast iron engine block cleaning.

Fundamentals of Ultrasonic Cleaning Technology

An industrial ultrasonic cleaner works by converting electrical energy into high-frequency mechanical vibrations through ultrasonic transducers. These vibrations propagate through a liquid medium, typically water-based solutions with appropriate detergents, generating a phenomenon known as cavitation.

Cavitation occurs when alternating high-pressure and low-pressure sound waves form microscopic bubbles in the liquid. These bubbles grow and then collapse violently within milliseconds. The collapse releases localized energy in the form of micro-jets and shock waves. Although invisible to the naked eye, these micro-impacts are powerful enough to dislodge grease, carbon, metal fines, and other contaminants from solid surfaces.

The key advantage of ultrasonic cleaning lies in its ability to clean without direct mechanical contact. This allows contaminants to be removed from internal passages, narrow gaps, and irregular surfaces without scratching or damaging the base material.

The Role of Frequency in Cavitation Energy

Ultrasonic frequency determines the size and energy of cavitation bubbles. Lower frequencies generate larger bubbles that collapse with greater force, while higher frequencies produce smaller bubbles with gentler cleaning action.

At 28kHz, cavitation bubbles are large and energetic, producing a strong mechanical cleaning effect. This makes the frequency particularly suitable for rugged materials such as cast iron, steel, and heavy alloys. Engine blocks, transmission housings, cylinder heads, and similar components benefit from this aggressive yet controlled cavitation environment.

Higher frequencies, such as 40kHz or above, are typically used for delicate parts like electronic components or precision instruments. While effective for light contamination, they often lack the impact force required to remove thick oil sludge and carbon buildup commonly found on engine blocks.

Why 28kHz Excels in Cast Iron Engine Block Cleaning

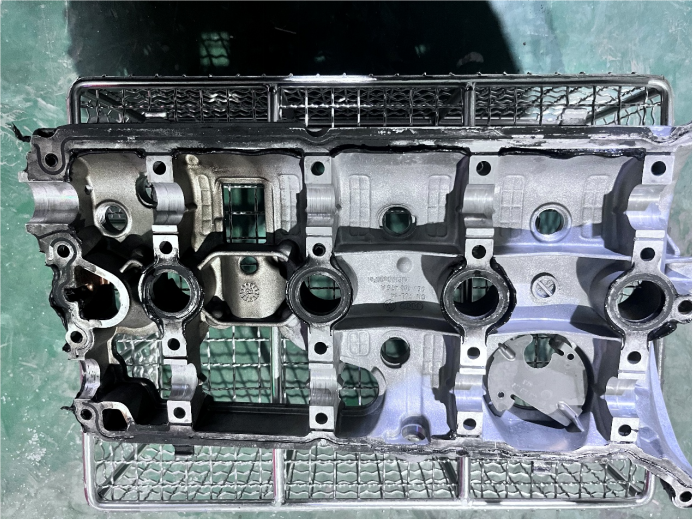

Cast iron engine blocks present unique cleaning challenges. Their porous surface structure tends to trap oil and carbon deep within the material. In addition, complex internal oil channels and cooling passages are inaccessible to brushes or spray systems.

The high cavitation intensity produced at 28kHz penetrates these internal structures effectively. The collapsing bubbles create micro-turbulence that flushes contaminants out of deep cavities, blind holes, and intersecting channels. This ensures uniform cleaning across the entire component, not just visible surfaces.

Another critical factor is durability. Cast iron components are mechanically robust and can withstand the higher cavitation energy associated with low-frequency ultrasonic cleaning. This allows manufacturers and service providers to maximize cleaning efficiency without risking surface erosion or structural damage.

As a result, 28kHz ultrasonic cleaning machines are widely adopted in auto parts cleaning, engine remanufacturing, marine maintenance, and aviation ground support operations.

Industrial Applications in Remanufacturing and Maintenance

In the automotive remanufacturing industry, engine blocks must be cleaned thoroughly before inspection, machining, or reassembly. Residual contaminants can compromise dimensional accuracy, bearing performance, and lubrication efficiency. Ultrasonic cleaning at 28kHz ensures that all internal passages are free from debris, improving rebuild quality and reducing failure rates.

Marine and aviation maintenance facilities face similar challenges. Engine components exposed to fuel residues, salt contamination, and high-temperature carbon deposits require deep, non-destructive cleaning. Industrial ultrasonic cleaners operating at 28kHz provide a reliable and repeatable process that meets strict maintenance standards while reducing labor intensity and chemical consumption.

Industrial Solutions from Tense

Tense ultrasonic cleaners are designed to meet the demands of heavy industrial cleaning. Optimized for 28kHz operation, these systems provide strong cavitation performance suitable for large, heavy components such as cast iron engine blocks. Their industrial-grade construction supports continuous operation in demanding environments, making them a preferred choice for auto maintenance workshops and remanufacturing plants.

The equipment is a single-tank integrated ultrasonic cleaning machine, which uses a weak alkaline water-based cleaning agent. The operator puts the workpiece into the tank through the tool to complete the cleaning of the parts within the set temperature and time. It can effectively remove oil stains and impurities on the inner and outer surfaces of the workpiece.

Features:

1.Digital control set cleaning time and temperature.

2.Tank is Made of SUS304,thickness from1.5 to 2.5mm.

3.Mobile casters

4.Horizontal support adjustment

5. Part of the equipment is equipped with pneumatic auxiliary

6.Oil skimmer for A type cleaner

|

Model |

TS-3600A |

TS-4800A |

TSD-6000A |

TSD-7000A |

TSD-8000A |

|

Dimension (mm) |

1460 x 1240 x 920 |

1680 x 1220 x 970 |

1880×1440×1100 |

2300×1800×1460 |

2600×1950×1600 |

|

Volume(ltr) |

308 |

430 |

780 |

1147 |

1600 |

|

Tank size (mm) |

1000×550×560 |

1200×600×600 |

1400×800×700 |

1700×900×750 |

2000×1000×800 |

|

Useful size (mm) |

920×510×420 |

1170×560×490 |

1260×690×560 |

1530×730×580 |

1860×860×680 |

|

Heating (KW) |

10.0 |

10.0 |

22.0 |

22.0 |

30.0 |

|

Ultrasonic power(KW) |

1.8 |

3.5 |

5.3 |

12.0 |

16.0 |

|

Transducer Qty. (pcs) |

40 |

60 |

96 |

128 |

200 |

Conclusion

Selecting the correct ultrasonic frequency is essential for achieving optimal industrial cleaning results. For cast iron engine blocks and other heavy-duty components, 28kHz delivers the ideal balance of cavitation strength, penetration capability, and material safety. Its proven effectiveness across automotive, marine, and aviation industries explains why it has become the gold standard in industrial ultrasonic cleaning.

By adopting professional ultrasonic cleaning machines operating at 28kHz, manufacturers and service providers can improve cleaning consistency, extend component lifespan, and enhance overall operational efficiency.

If you are looking for reliable, temperature-controlled ultrasonic cleaning equipment, China Tense offers a full range of industrial ultrasonic cleaning machines designed for high-efficiency performance across demanding applications.

Post time: Feb-10-2026