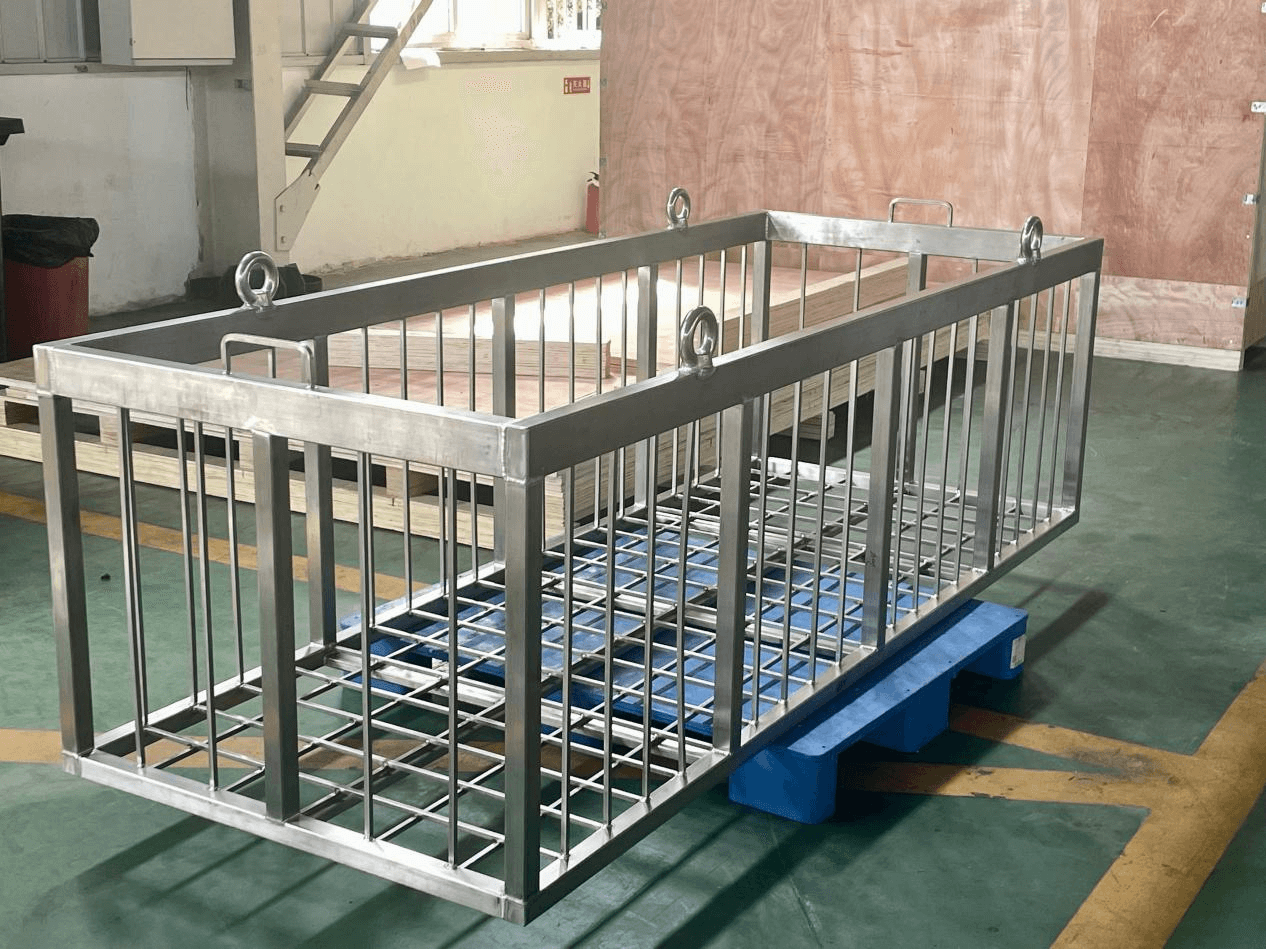

Recently, TENSE successfully completed the delivery of a custom-designed large single-tank ultrasonic cleaning machine for a client in the automotive parts industry. The machine was specially engineered to handle oversized and heavy components with high-efficiency cleaning requirements. After passing thorough internal testing, the equipment has now been shipped to the customer site.

Unlike standard cleaning systems, this project required a non-standard solution tailored to the customer’s workflow. The delivered system integrates high-power ultrasonic cleaning with intelligent automation, aiming to significantly reduce labor input while improving cleaning precision and consistency.

The machine features several key technical highlights:

Large-capacity single tank: Designed to accommodate large or bulky parts such as cylinder blocks, brake components, and gearbox housings.

High-power ultrasonic transducers: Ensures deep, uniform penetration into complex geometries to remove oil, carbon deposits, and metal chips.

Air bubbling assistance: Enhances agitation in the cleaning fluid for better contaminant removal.

Circulation filtration system: Continuously filters the cleaning solution to extend liquid life and reduce maintenance costs.

Intelligent control panel: Centralized operation interface for temperature, time, and safety control.

Modular structure: Ready for future upgrade or integration with automated loading/unloading.

The machine is especially suitable for automotive manufacturing lines, machining workshops, and repair depots. It is capable of removing typical contaminants generated during cutting, stamping, or heat treatment processes. By reducing manual cleaning steps, the system helps customers save on labor costs and achieve a more standardized and reliable cleaning process.

Despite the technical complexity of the equipment, the TENSE engineering and production teams ensured fast execution from design to delivery. The customer appreciated the high level of customization, attention to detail, and the commitment to delivery timelines.

In ultrasonic cleaning equipment, transducers transmit high-frequency mechanical vibrations into the cleaning solution, inducing cavitation effects within the liquid. The formation and sudden collapse of cavitation bubbles release high-energy shock waves, effectively removing oils, particles, and microscopic impurities adhering to the surface of workpieces. The performance metrics of transducers include frequency response, power handling capacity, amplitude, and mechanical coupling efficiency, which directly determine the intensity and uniformity of the cleaning process.

This large single-tank ultrasonic cleaning machine is equipped with 382 high-performance transducers, significantly expanding the coverage of ultrasonic energy and enhancing cleaning efficiency, ensuring uniform and thorough cleaning of every corner of large, complex workpieces.

A reasonable array layout ensures uniform distribution of ultrasonic energy within the cleaning tank, avoiding “dead zones” and areas of weak energy, thereby improving overall cleaning performance. Transducers must also be equipped with impedance matching networks and drive circuits to optimize electro-mechanical conversion efficiency and reduce system energy consumption.

The final equipment has now been shipped. A short delivery video is available upon request or via our social platforms.

TENSE continues to specialize in advanced industrial cleaning equipment with a strong focus on customer-specific solutions. We welcome partners across various industries to explore our ultrasonic cleaning systems and develop tailored equipment together.

Recently, TENSE successfully completed the delivery of a custom-designed large single-tank ultrasonic cleaning machine for a client in the automotive parts industry. The machine was specially engineered to handle oversized and heavy components with high-efficiency cleaning requirements. After passing thorough internal testing, the equipment has now been shipped to the customer site.

Unlike standard cleaning systems, this project required a non-standard solution tailored to the customer’s workflow. The delivered system integrates high-power ultrasonic cleaning with intelligent automation, aiming to significantly reduce labor input while improving cleaning precision and consistency.

The machine is especially suitable for automotive manufacturing lines, machining workshops, and repair depots. It is capable of removing typical contaminants generated during cutting, stamping, or heat treatment processes. By reducing manual cleaning steps, the system helps customers save on labor costs and achieve a more standardized and reliable cleaning process.

Despite the technical complexity of the equipment, the TENSE engineering and production teams ensured fast execution from design to delivery. The customer appreciated the high level of customization, attention to detail, and the commitment to delivery timelines.

The final equipment has now been shipped. A short delivery video is available upon request or via our social platforms.

TENSE continues to specialize in advanced industrial cleaning equipment with a strong focus on customer-specific solutions. We welcome partners across various industries to explore our ultrasonic cleaning systems and develop tailored equipment together.

Post time: Jul-25-2025