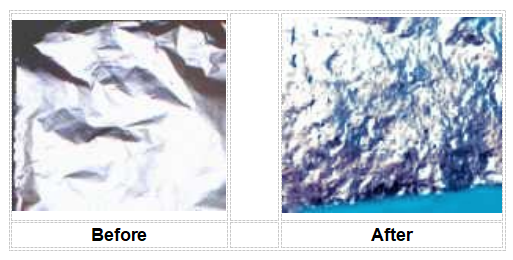

1.Obtain a piece of standard household aluminium foil measuring approx. 1 inch greater than the depth of the tank by approximately the width (long dimension) of the tank.

2.Before placing the foil in the tank, turn the ultrasonic cleaner on for few minutes to degas.

3.Place foil sample which was prepared in step 1 into the tank in a vertical position. The foil long dimension should be positioned with the long tank dimension. The foil should extend downward, but should not touch the tank bottom. This is illustrated below.

4.Hold the foil as steady as possible to the centre of the tank and turn the ultrasonic cleaner on for 10-15 seconds.

5.Turn the cleaner off and remove the foil sample. Shake the foil sample dry of any water droplets.

6.The result will show that foil surfaces are uniformly perforated and evenly covered with tiny pebbling effect over the entire surface.

7.Our aluminium foil test result exhibits a greater density of prick pin holes and perforations with more uniform and even distribution of ultrasonic cleaning power throughout the liquid. Will your ultrasonic cleaner achieve this result?

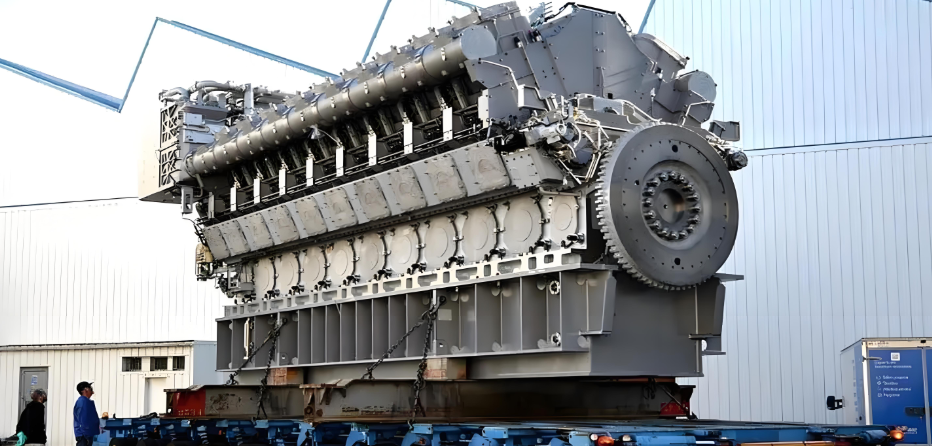

Marine engine maintenance, high-precision ultrasonic cleaning

ultrasonic high-precision cleaning As the “heart” of a ship, its operating status directly affects the ship’s navigation efficiency, fuel economy, and safety.

Thoroughly cleaning oil contaminated parts is a crucial step in engine maintenance and repair. Conventional manual cleaning is far from meeting the high standards of cleaning requirements. Due to the long-term operation of marine engines in harsh environments such as high temperature, high humidity, and high salt spray, oil sludge, carbon deposits, and corrosion products generated by incomplete fuel combustion, lubricating oil oxidation, and metal wear will deposit on the surfaces of components.

If not cleaned in a timely manner, it will seriously affect the performance and lifespan of the engine. The maintenance and cleaning of marine engines is not simply about “removing oil stains”, but involves systematic engineering in terms of performance, safety, cost, and environmental protection. Through scientific and standardized cleaning and maintenance, ship operators can not only improve engine reliability, but also reduce full lifecycle costs and meet increasingly stringent environmental requirements. Every thorough maintenance and cleaning is an investment in the long-term voyage of the ship.

Traditional manual cleaning methods include solvent soaking, chemical scrubbing, and high-pressure water rinsing, which have many uncontrollable factors such as low cleaning efficiency, poor environment, and high cost. Ultrasonic cleaning can effectively remove oil sludge, stains, and carbon deposits inside and outside the components. And the physical cleaning method will not cause any physical damage to the components.

Ultrasonic cleaning technology has become the preferred method for cleaning oil contaminated parts of marine engines due to its high efficiency, precision, and environmental characteristics, especially suitable for high-precision and high-quality cleaning of precision components and engine disassembly parts.

The core advantages of ultrasonic cleaning in marine engine maintenance are as follows:

Ultrasonic cleaning provides thorough cleaning with no dead corners. Marine engine components often have complex structures like deep holes, threads, and blind holes (such as fuel injectors and piston ring grooves), which are difficult to clean completely with traditional brushing or high-pressure water. The cavitation effect of ultrasound generates micro-sized bubbles that burst with high-frequency shock waves (usually 20–40kHz), allowing them to penetrate fine gaps and remove dirt. This makes ultrasonic waves particularly effective for cleaning stubborn residues like carbon deposits (from high-temperature combustion), gelatinous sludge (from oxidized lubricants), and salt crystals (from seawater corrosion), all while protecting the surface of components.

Another key benefit is non-contact cleaning, which avoids surface damage. Mechanical brushing can scratch precision surfaces like crankshaft necks and turbine blades, while ultrasonic energy travels through a liquid medium without direct contact. This preserves the original smoothness of parts. It’s also compatible with a variety of materials, including steel, aluminum, copper, rubber sealing rings, and plastics (with temperature control). To minimize corrosion, neutral or weakly alkaline cleaning agents—such as water-based degreasers—can be used instead of strong acids or alkalis, which may harm aluminum alloys or coatings.

Ultrasonic cleaning is also efficient and cost-saving. Traditional soaking can take several hours, but ultrasonic cleaning usually completes the job in 10–30 minutes, depending on how dirty the parts are. Some ship repair plants report a 40% reduction in engine overhaul time. It also significantly reduces manpower—no need for repeated manual brushing—and cleaning agents can be reused, cutting down on waste treatment costs.

Lastly, there are environmental and safety advantages. The use of toxic solvents like diesel and kerosene can be greatly reduced or eliminated. Ultrasonic cleaning agents are typically low in toxicity and easy to neutralize, meaning lower waste disposal costs. Additionally, the equipment operates in a closed environment, reducing the risk of vapor explosion or fire hazards common with open solvent use.

In summary, ultrasonic cleaning offers deep cleaning, protects parts, saves time and money, and supports safer and greener engine maintenance. For ship operators aiming for zero-fault performance and environmental compliance, it’s a practical solution that boosts both efficiency and reliability.

| Model | TS-800 | TS-2000 | TS-3600 | TS-4800 | TSD-6000 | TSD-7000 | TSD-8000 |

| Capacity | 47ltr. | 120ltr. | 308ltr. | 430ltr. | 780ltr. | 1140ltr. | 1600ltr. |

| Oversize | 85×68×59cm | 115×71×68cm | 146×100×90cm | 168×105×92cm | 186×129×104cm | 246×180×146cm | 260×195×160cm |

| Tank inner size | 45×35×30cm | 75×40×40cm | 100×55×56cm | 12×60×60cm | 140×80×70cm | 170×90×75cm | 200×100×80cm |

| Useful size | 37×30×21cm | 67×36×30cm | 92×51×42cm | 117×56×49cm | 126×69×56cm | 153×73×58cm | 186×86×68cm |

| Heating | 2.5kw | 6.6kw | 10kw | 10kw | 22kw | 22kw | 30kw |

| Ultrasound | 0.8kw | 1.6kw | 3.2kw | 4.8kw | 8.0kw | 12kw | 16kw |

Post time: Jul-23-2025