In industrial production, in addition to ensuring product quality, production safety is also crucial. In particular, the safety of equipment must be strictly operated in accordance with specifications to avoid unnecessary man-made accidents. TENSE hydrocarbon cleaning machine equipment uses hydrocarbon cleaning agent (or modified alcohol) as a cleaning agent; the equipment is monitored by a PLC control system and works fully automatically; it works in a working chamber and integrates 360° rotation of the tooling basket (parts), ultrasonic cleaning, spray cleaning, steam cleaning (optional), vacuum drying and other functions; all processing processes are carried out in a vacuum environment, thereby ensuring safety. The equipment can be equipped with a built-in hydrocarbon distillation recovery device to minimize production costs.

Hydrocarbons are flammable and explosive. Safety and proper operation should be taken into consideration during storage, cleaning and recycling. For our hydrocarbon ultrasonic cleaning machine, we should pay attention to the following aspects:

1、Safety of hydrocarbon cleaning machine tank

Tense hydrocarbon cleaning machine has advanced anti-leakage design and explosion-proof device, equipped with precise temperature control system and high-precision liquid level sensor to ensure safe operation. The equipment also has a good exhaust system, reliable grounding protection and pneumatic valve and automatic control system to improve operational safety. We also provide regular maintenance services to ensure that the equipment is always in the best condition.

2、Hydrocarbon cleaning machine transportation safety

Before transporting a hydrocarbon cleaning machine, prepare it, including training operators, checking the equipment, and planning the route. Use the right tools to make sure the equipment is stable and doesn't shake. Follow the manual and wear safety equipment. After transporting, check the equipment is intact and recalibrate it. Develop an emergency plan and deal with any problems quickly.

3、Electrical Safety

The electric control box is connected to compressed air in order to isolate it from the external environment. Similarly, the relay box is connected to compressed air in order to isolate it from the external environment. Furthermore, all processing is carried out in a vacuum environment, thus ensuring safety.

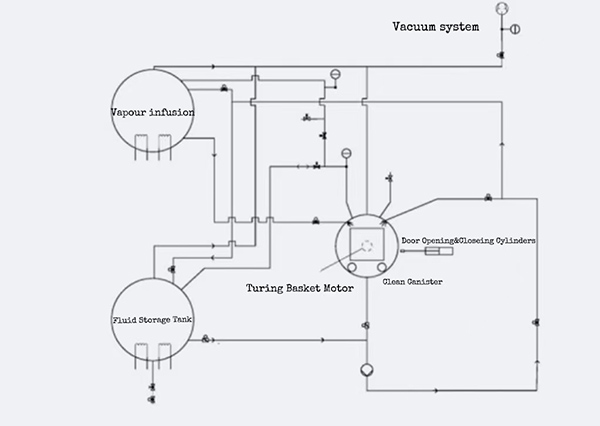

(Hydrocarbon Cleaner Working Principle Diagram)

TENSE is committed to the development, production and sales of industrial cleaning equipment; Inquiries are welcome.

How to ensure the safe operation of hydrocarbon cleaning machines

In industrial production, in addition to ensuring product quality, production safety is also crucial. In particular, the safety of equipment must be strictly operated in accordance with specifications to avoid unnecessary man-made accidents. TENSE hydrocarbon cleaning machine equipment uses hydrocarbon cleaning agent (or modified alcohol) as a cleaning agent; the equipment is monitored by a PLC control system and works fully automatically; it works in a working chamber and integrates 360° rotation of the tooling basket (parts), ultrasonic cleaning, spray cleaning, steam cleaning (optional), vacuum drying and other functions; all processing processes are carried out in a vacuum environment, thereby ensuring safety. The equipment can be equipped with a built-in hydrocarbon distillation recovery device to minimize production costs.

The core principle of ultrasonic cleaning is the cavitation effect - high-frequency sound waves are transmitted through liquid media to generate tiny bubbles that burst and impact. In the no-load state (i.e., there is no cleaning liquid in the tank or the liquid is insufficient), the energy transmission chain is forcibly interrupted, which may cause the ultrasonic transducer to be destroyed.

l Risk of uncontrolled cavitation effect

Under no-load condition, the energy balance of the ultrasonic system is broken, causing dangerous phenomena:

l Standing wave formation

The lack of liquid causes the sound waves to reflect repeatedly between the tank walls, forming fixed standing wave nodes. The energy density at these nodes can reach 20 times the normal value, which may break through the stainless steel layer of the tank body (risk [sensitive word] when the thickness is less than 1mm).

Cavitation explosion

The residual droplets oscillate violently in the strong sound field, and the instantaneous temperature generated by the rupture of a single bubble exceeds 5000°C (close to the surface temperature of the sun). Although it lasts only microseconds, it is enough to leave pits on the metal surface.

l Emergency treatment and daily protection guide

1. Emergency measures for accidental no-load

Immediate power off: If no-load operation is found, turn off the power within 10 seconds (the damage rate will increase by 80% if it exceeds 30 seconds)

Natural cooling: Wait for the equipment to cool completely (about 2 hours) before filling and testing

Function test: After restarting, run at [sensitive word] power first, confirm that there is no abnormal noise, and then resume normal use

2. Daily operation specifications

Pre-filling standard: liquid level height ≥ 4/5 of the tank height, submerging the transducer by at least 2cm

Drug selection: Avoid using pure water (low conductivity affects the sensor), it is recommended to add 0.5% special cleaning agent

Regular maintenance:

Check whether the liquid level sensor is the same every week

Clean the tank with citric acid solution (5%) every month to prevent scale from interfering with this notification

Hydrocarbons are flammable and explosive. Safety and proper operation should be taken into consideration during storage, cleaning and recycling. For our hydrocarbon ultrasonic cleaning machine, we should pay attention to the following aspects:

1、Safety of hydrocarbon cleaning machine tank

Tense hydrocarbon cleaning machine has advanced anti-leakage design and explosion-proof device, equipped with precise temperature control system and high-precision liquid level sensor to ensure safe operation. The equipment also has a good exhaust system, reliable grounding protection and pneumatic valve and automatic control system to improve operational safety. We also provide regular maintenance services to ensure that the equipment is always in the best condition.

2、Hydrocarbon cleaning machine transportation safety

Before transporting a hydrocarbon cleaning machine, prepare it, including training operators, checking the equipment, and planning the route. Use the right tools to make sure the equipment is stable and doesn't shake. Follow the manual and wear safety equipment. After transporting, check the equipment is intact and recalibrate it. Develop an emergency plan and deal with any problems quickly.

3、Electrical Safety

The electric control box is connected to compressed air in order to isolate it from the external environment. Similarly, the relay box is connected to compressed air in order to isolate it from the external environment. Furthermore, all processing is carried out in a vacuum environment, thus ensuring safety.

(Hydrocarbon Cleaner Working Principle Diagram)

TENSE is committed to the development, production and sales of industrial cleaning equipment; Inquiries are welcome.

Post time: Jul-28-2025