A cabinet washer, also known as a spray cabinet or spray washer, is a specialized machine designed for thorough cleaning of various components and parts. Unlike manual cleaning methods, which can be time-consuming and labor-intensive, a cabinet washer automates the cleaning process, saving both time and effort.

Introduction:

These versatile machines come in different sizes and configurations, allowing them to accommodate a wide range of items, from small components to large industrial parts. The cleaning chamber of a cabinet washer is typically equipped with spray nozzles strategically placed to deliver a powerful and targeted cleaning solution onto the parts being cleaned.

The cleaning solution used in a cabinet washer is specifically formulated to remove dirt, grease, oil, and other contaminants from the components. This is achieved through a combination of mechanical action, such as the pressure and flow of the cleaning solution, and the chemical properties of the detergent used. The industrial cabinet washer ensures that every nook and cranny of the parts are thoroughly cleaned, even in hard-to-reach areas.

Advantages:

One of the key benefits of a industrial parts washer is its efficiency. These machines can clean multiple components simultaneously, resulting in a significant increase in productivity compared to manual cleaning methods. Additionally, the automated nature of the cabinet washer allows operators to focus on other tasks, maximizing their efficiency and reducing labor costs.

The use of a cabinet washer also enhances cleaning consistency and accuracy. Unlike human operators, machines do not suffer from fatigue or variations in cleaning technique, ensuring a consistent level of cleanliness for each component. This is especially crucial in industries with strict quality control standards, such as automotive, aerospace, and medical manufacturing.

Furthermore, cabinet washers are designed with safety in mind. They are equipped with built-in safety features, such as interlocks and shields, to protect operators from potential hazards, such as high-pressure sprays or harmful chemicals. These safety measures not only safeguard the well-being of the personnel but also contribute to a more secure working environment.

Applications:

The applications of cabinet washers are diverse, spanning across various industries. From automotive and aerospace to electronics and food processing, these machines find their utility in cleaning a wide range of components, including engine parts, electronic circuit boards, kitchen utensils, and more. Their versatility and adaptability make them an indispensable tool for industries that prioritize cleanliness and efficiency.

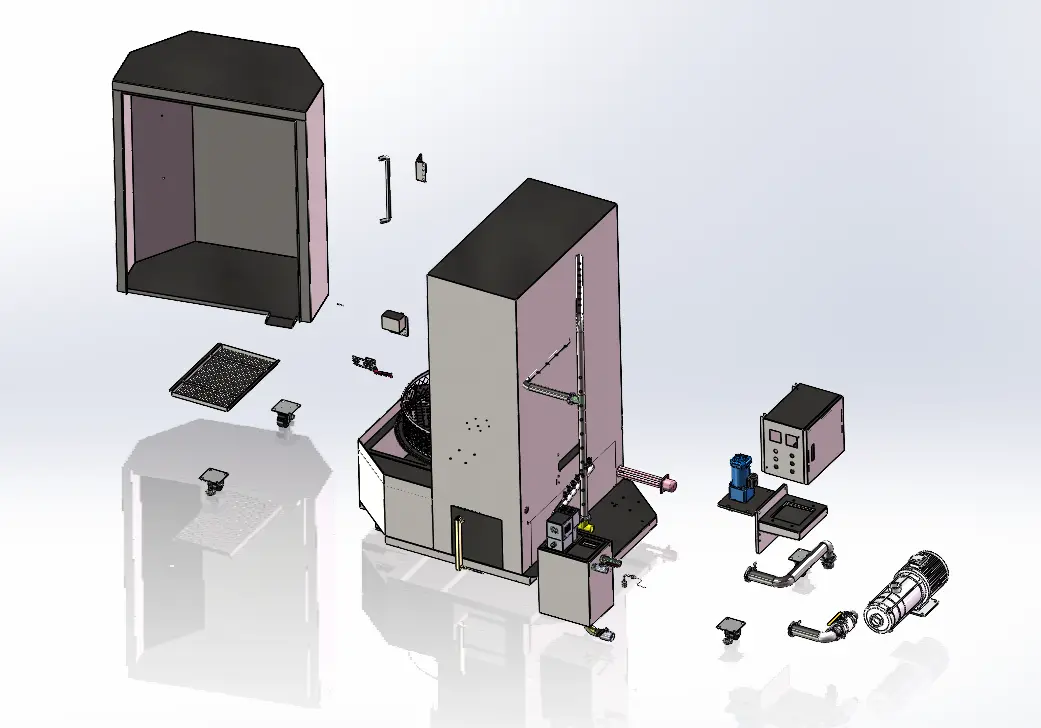

INDUSTRIAL CABINET PARTS WASHERS TS-P SERIES:

The TS-P series industrial cabinet parts washer is a simplified and lightweight design based on the TS-L-WP series. The operator places the parts on the cleaning cabinet platform and starts up.

During the cleaning process, the basket is driven by the motor to rotate 360 degrees, and the stainless steel nozzles installed in multiple directions are sprayed to wash the parts; the cleaning work is completed within the set time, and the parts can be manually removed by opening the door. The cleaning medium in the tank can be recycled.

| Model | Dimension | Turntable diameter | Cleaning height |

|

TS-P800 |

150*140*191cm |

80cm |

100cm |

| Load capacity | Heating | Pump | Pressure | Pump flow |

|

220kg |

11kw |

4.4KW |

5bar |

267L/min |

We specialize in the production of industrial cleaning equipment, accept OEM cooperation. Check more of our industrial cleaning machines.

Post time: Sep-20-2023