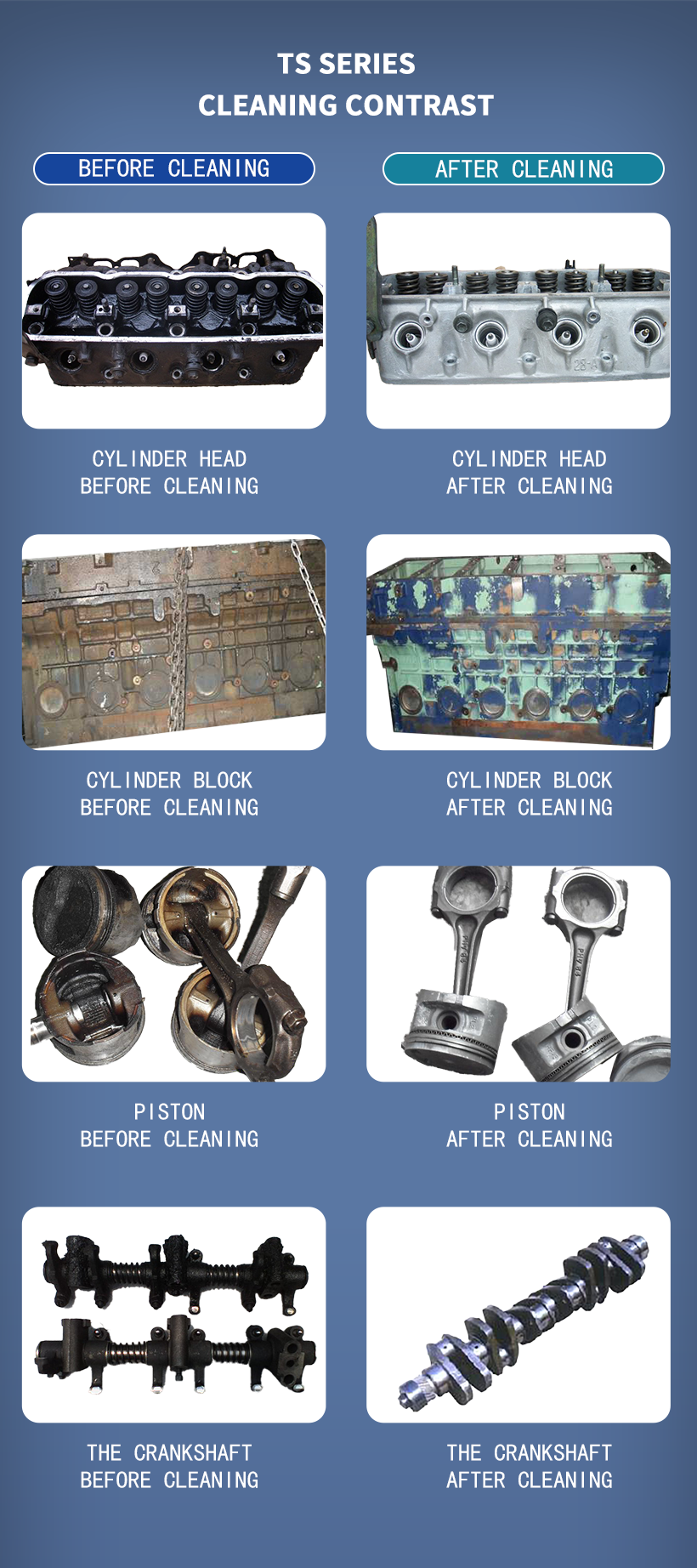

Ultrasonic cleaning machine has been specifically designed for the cleaning and degreasing of all type of parts and components in Automotive industry. It achieves excellent cleaning results in many types of materials, especially in complex parts, where the ultrasounds have excellent results thanks to its high penetration capacity. Thus, the results while cleaning automobile engines are spectacular, even in those smaller and delicate parts.Our Automotive series uses 28 kHz frequency with which the best results for the Automotive Sector are achieved.

{TS-3600A}

The main functions of the equipment include: digital display temperature control, digital display timing, ultrasonic cleaning; the equipment is equipped with casters and horizontal adjustment brackets, which can be easily moved, and equipped with manual water inlet, drainage and overflow. For some larger models, an additional pneumatic door opening assist is available. After the cleaning is completed, turn on the circulation function with one key, and the oil scraper starts to work at this moment, so that the liquid in the tank can be recycled.

Power supply:

We use 3*380V for the conventional power supply of the equipment, and also support the customization of other different power supplies, such as 3*220V, etc. Please pay attention when ordering the equipment. All parts of the cleaning equipment in contact with water are made of SUS304 material.

During cleaning, oil, grease and light dirt will raise to the surface of the water. If this is not removed, the cleaned components will become dirty as they are raised up through the surface.

The surface skimmer function flushes the water surface after each cleaning cycle, before the basket is raised out of the tank. This ensures completely clean components after each cleaning cycle. The dirt, oil & grease removed from the surface is collected in the oil skimmer where oil and grease is skimmed off.

| Volume | 308 liters | 81gallons |

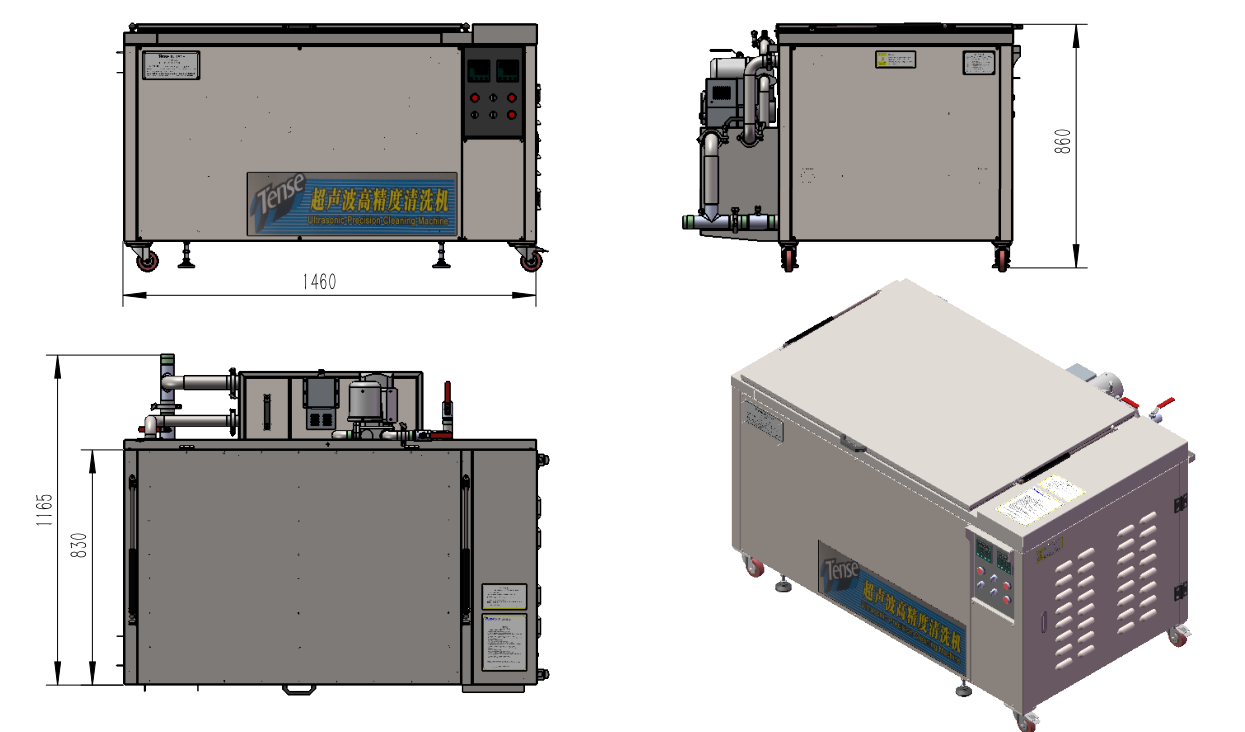

| Dimensions (L×W×H) | 1460 x 1165 x 860mm | 57”x45”x33” |

| Tank size (L×W×H) | 1000 x 550 x 560 | 39"×21"×22" |

| Useful size (L×W×H) | 915 x 440x 430 | 36"×20"×16" |

| Ultrasonic power |

3.2 Kw |

|

| Ultrasonic frequency |

28KHZ |

|

| Heating power |

10 Kw |

|

| Oil skimmer effect |

15W |

|

| Circulating pump power |

200W |

|

| G.W. |

380KG |

|

| Packing Size (mm) |

1560x1350x1080mm |

|

1) The general working temperature of the ultrasonic cleaner is about 55 degrees (131℉), and the long-term working temperature should not exceed 75 degrees(167℉);

2) It is forbidden to turn on the ultrasonic and heating functions without adding liquid;

3) The parts need to be put into the cleaning tank for cleaning through the basket, and it cannot be directly put into the working tank for cleaning;

4) When the parts are placed and taken out of the cleaning tank, turn off the ultrasonic work first;

5) The choice of cleaning detergent should satisfy 7≦Ph≦13;

6)The moving device of the equipment is only used for the moving position of the tank body when it is vacant, and cannot be used to fill the liquid or clean the parts frequently.

{movie}

The high-efficiency cleaning effect and low-cost investment of industrial single-tank ultrasonic cleaning equipment are very popular with customers. This series of cleaning equipment is widely used in some auto repair shops, engine and gearbox maintenance companies and some construction machinery maintenance companies. Through cleaning the processing of the machine can bring a very good effect to the surface of the aluminum alloy metal, and even restore the luster of the surface of the new part. It has a very obvious effect on the cleaning of carbon deposits in the exhaust holes of the engine cylinder head; it also has a very obvious cleaning effect on some very precise parts in the gearbox, such as valve plates.

{photo}

Common customer groups Car maintenance, boring cylinder grinder center, gearbox maintenance,remanufacturing maintenance industry.

Post time: Nov-25-2022