For this series of ultrasonic single-tank equipment, we have models with different volumes to meet customer needs. The current standard equipment is 780 liters, 1100 liters, and 1600 liters.

This series of cleaning equipment has a large volume, the stainless steel heating tube can be quickly heated, and the temperature and cleaning time can be set digitally. The ultrasonic frequency of 28KHZ can efficiently clean the surface of metal parts.

For 1100 liters and 1600 liters of equipment, we use pneumatic door opening, which is more convenient for customers to operate.

For the material frame of the equipment configuration, all are made of SUS304 material. It can meet the cleaning of larger weight parts.

{TSD-6000A}

Function

Oil skimmer function

During cleaning, oil, grease and light dirt will raise to the surface of the water. If this is not removed, the cleaned components will become dirty as they are raised up through the surface.

The surface skimmer function flushes the water surface after each cleaning cycle, before the basket is raised out of the tank. This ensures completely clean components after each cleaning cycle. The dirt, oil & grease removed from the surface is collected in the oil skimmer where oil and grease is skimmed off.

Specification

| Volume | 784 liters | 205 gallons |

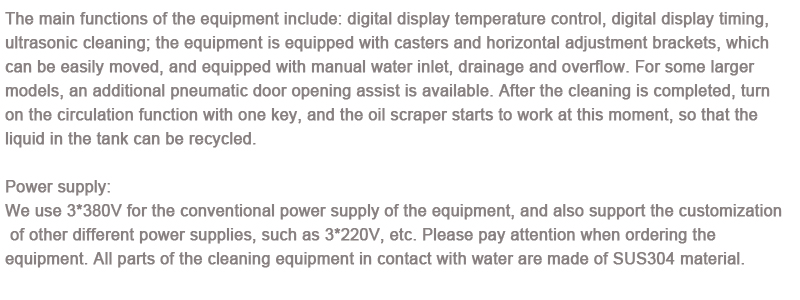

| Dimensions (L×W×H) | 1860×1490×1055mm | 73”×58”×41” |

| Tank size (L×W×H) | 1400×800×700mm | 49"×31"×27" |

| Useful size (L×W×H) | 1260×690×550mm | 49"×27"×22" |

| Ultrasonic power |

8.0 Kw |

|

| Ultrasonic frequency |

28KHZ |

|

| Heating power |

22 Kw |

|

| Oil skimmer (W) |

15W |

|

| Circulating pump power |

200W |

|

| Packing Size (mm) |

1965×1800×1400mm |

|

| G.W. |

690KG |

|

Attentions

1)According to standard, equipment must be grounded

2)Do not use wet hands to operate buttons to prevent electric shock or electrical damage.

3)Workpiece placed in actual carrying baskets prevail , not blindly placing cause serious distortion baskets

4)Hot water ( temperature ≥ 80 ℃) can not be directly added to cleaning tank.

5)Must be cleaned by specifying tooling prohibited parts directly into the tank cleaning

6)Lifting into the slot , to ensure slow into slow out, avoid , throw, hit , crash .

7)When removed the machine, Ensure that all off the zero line connection is correct before use.

8)Replacement due to damage electrical components should be strictly in accordance with the electrical wiring diagram , do not arbitrarily replace the wiring and specifications

9)material box into the platform components shall not exceed four with peripheral, nor under the fixed plate.

Applications

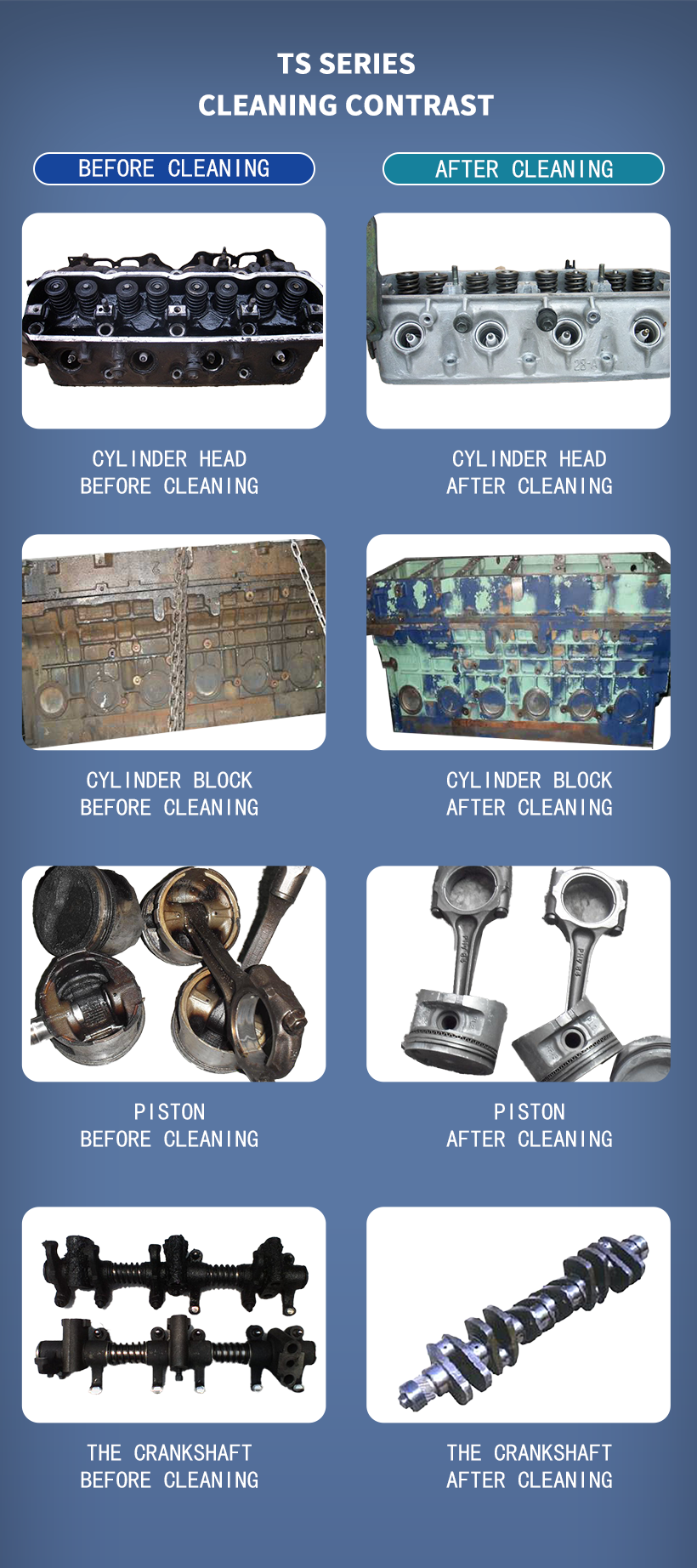

Tense's industrial ultrasonic cleaning machine can better meet the needs of surface cleaning of metal parts, please check the effect comparison chart with pictures; it can clean cylinders, cylinder blocks, cylinder heads, pistons, crankshafts, connecting rods, etc.

(finished)

Post time: Oct-30-2022